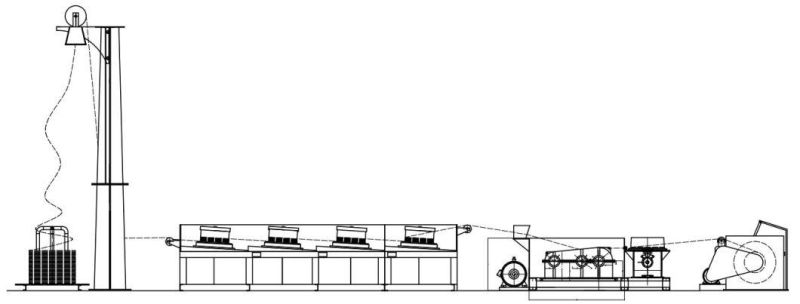

6.5mm Steel/Iron Straight Wire Drawing Machine From Factory

SHIJIAZHUANG SATLE MACHINERY MANUFACTURE CO., LTD.- Type:Bearing

- Application:Wire Draw

- Certification:CE, ISO9001: 2000

- Condition:New

- Material:Steel

- Color:Free Choose

Base Info

- Model NO.:LZ550

- Package:Whole

- Transport Package:Whole Package

- Specification:1300L*1820W*1260H (mm)

- Trademark:Satle

- Origin:Shijiazhuang China

Description

Basic Info.

Model NO. LZ550 Package Whole Transport Package Whole Package Specification 1300L*1820W*1260H (mm) Trademark Satle Origin Shijiazhuang ChinaProduct Description

The machine has a modular structure and is combined with blocks without any special foundation.

Increased productivity due to higher drawing speeds, no distortion and better cooling.

The operation is simple and the thread is faster.

High reliability and low downtime. Wear parts.

Wire quality is better accomplished due to smoother handling of wires (less wire deviation, low twist, etc.) and optimized wire cooling during the drawing process.

Technical breakthrough, automatic control of winch (hub), single-group brake emergency stop function, efficient pneumatic brake system in emergency situations.

Increased flexibility and lower current consumption thanks to modern AC drive technology and efficient power transmission system

PLC intelligent control system

Dimension: 1300L*1820W*1260H (mm)

Net weight: 1800KG

Max. entering (steel) wire strength:≥700MPa

Entering (steel) wire dia.:Ф6.5mm

Exiting (steel) wire dia.:Ф2.0mm

Pulling steel wire material:low carbon steel

Max. steel wire drawing speed:15m/s ( Normal using speed: 10m/s)

Water volume :6m3/h (Water pressure ≥0.25MPa)

Air volume:1.5m3/h (Air pressure ≥0.6MPa)

Motors:first draw 30KW, others 22KW AC freq. con. Motor

Technical advantages

The machine has a modular structure and is combined with blocks without any special foundation.

Increased productivity due to higher drawing speeds, no distortion and better cooling.

The operation is simple and the thread is faster.

High reliability and low downtime. Wear parts.

Wire quality is better accomplished due to smoother handling of wires (less wire deviation, low twist, etc.) and optimized wire cooling during the drawing process.

Technical breakthrough, automatic control of winch (hub), single-group brake emergency stop function, efficient pneumatic brake system in emergency situations.

Increased flexibility and lower current consumption thanks to modern AC drive technology and efficient power transmission system

PLC intelligent control system

Drum

Material:steel ZG45~55, hardness alloy tungsten carbide is spraying-painted on working surface, with HRC60, roughness ≤1.6Ra.

Drum using life: two year

Drum cooling mode: narrow seam type water cooling for inner of drum

Die box

Welding part is adopted for the die box. It is adjusted in universal directions. The guide roller is in front of die box and coated with tungsten carbide. The die box is divided into lubrication cavity and cooling cavity. Ball valve adjusts water feeding flow. The position of die box can be adjusted to adapt the position of wire for drawing. The dancer arm wheel is in the entry of die box to adjust the drawing speed of every drawing block. It is driven by pneumatic cylinder.

Tension roller is made of special steel alloy and heat treated to have long working life.

The wire tension is detected by the TE sensor(none touch type) dynamically and feedback signal to the motor driver.

Electric Control system

Control System adopts AC frequency-variation speed adjusting drive and Siemens PLC system, and takes the most popular PROFIBUS type in the world, which not only operates stably and precisely , but also greatly improve the transit speed.

Operation: including touch screen, emergency button ready button, stop button, accelerate button, decelerate button, fault button and reset button. Touch screen is colorful and the brand is Weinview . The yield can be presented on the screen by the meter-counter or weight-counter. The drawing speed can be adjusted on the screen.

Control pulpit

a. On pulpit, all drawing drum running conditions can be displayed.

b. It can control all drums and the single taking-in machine by linkage.

c. It can regulate the running speed by integration.

d. At EMG stop, it can realize the integrated linkage and EMG stop for paying-off, drawing and taking-in, also ensures no wire confusion, no breaking.

e. Automatically alarm when failure displays and display the locations where the trouble may take place and the causes.

Inverter:SINE inverter is adopted.

Working mode

The system adopts the PLC control, inverter and contact screen generally. The digital exchanging is completed by communication. PLC is used to read, write, start and stop the inverter at will. PLC software ensures the auto program editing and setting for different drawing technics and ensures the running smoothly. Color screen man-machine interface system can monitor equipment running status and failure display. All technics parameters of system can be input from contact screen with high precision, strong correctness and easy modification. It also ensures the wide drawing technics and easily realizes the die jumped drawing. The whole system runs reliably with low failure rate and easily operation.

Layout Design

+8618000614657