Trenchless Npd 600 Slurry Pipe Jacking Machine for Pipeline

JIANGSU XUAN XUAN HEAVY MACHINERY CO., LTD.- Suitable Soil Condition:Mix Soil, Strata, Soil, Sandy

- Jacking Speed:3-5 Meter,Hour

- Power Capacity of The Machine:15kw

- Cutter Head Cutting Od:780

- Hydraulic Jack Jacking Force:2000kn X2

- Hydraulic Jack Pump:2 Pumps

Base Info

- Model NO.:NPD600

- Charge & Discharge Pump Motor:22kw

- Steering Angle:Maximun 2

- Cylinder Thrust:200kn X3

- Maximun Torque:13.3kn.M

- Transport Package:Woodencase

- Specification:Dia. 810X2800

- Trademark:Xuanxuan

- Origin:Jiangsu Changzhou

- HS Code:8430313000

Description

Bonfiglioli, ITALY

Application Scope:

Slurry Pipe jacking machine is widely used in underground water pipe ,oil pipe ,nature gas ,for trechless underground pipe laying projects, eg. sewage, water supply, discharging projects, cables, tunnel,various communication cable laying pipeline trenchless, This technology doesn't need excavation surface ,it push the pipe to the soil begin with star shaft,and it can curve ,overcome some underground pipeline obstacles.

Principle

Slurry Pipe jacking construction is trenchless (non-excavation)construction ,It is a non-excavation or less excavation of the pipeline embed construction technology.Pipe jacking construction is in the work in the pit by means of jacking equipment which produce jacking force, and overcome the friction between the pipes and the surrounding soil

Jacking the pipes Into the soil at the design slope.and Removed soils ,

After a section of pipe finish jacking into the soil , then the second section of the pipes continue to jack into the soil , The principle is by means of the thrust of the main cylinder pipeline, intermediate jacking station,and other thrust pushing the tool pipe or heading machine (through the soil )from working well to the receiving well and Lift up. Then , embed the pipes between the two wells

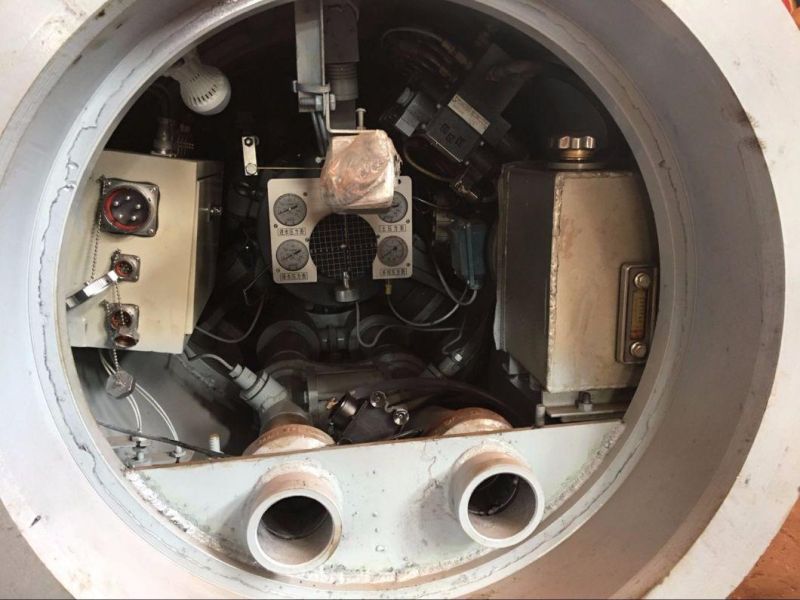

4.1 Machine Head selectionIn order to ensure the quality of the project and ensure the absolute safety of the project, our company decided to adopt the NPD-1000 and NPD-600 Balance pipe jacking machine.

The basic principle of the slurry balance pipe jacking machine is the main shaft eccentric rotation movement and broken,the front of the cutter plate with larger opening ,which is Easy for the bigger pebbles enter into the pipe jacking machine,The upper and lower sides of the enter port of the cutterhead .The area of the opening is about 15% ~ 20% of the total area of the full section of the Pipe jacking machine.

The cutterhead is driven by a motor provided on the left and right sides of the main shaft,The motor drives the pinion through the planetary reducer,And then drive the large gear located in the center,The big gear is connected to the main shaft and roll. The left end of the shaft is fitted with a cutterhead,As long as the cutter drive motor rotation, the cutterhead will rotate ,The roll also rotate

During the boring machine work, the cutterhead cutting down the sand while doing eccentric motion to crush the rocks. The stones that are crushed are only smaller than the gap between the soil chamber and the slurry tank ,then can enter into the slurry tank of the boring machine And then discharged from the slurry discharging pipe.Also, because of the cutterhead movement, the gap between the soil chamber and the slurry tank is constantly changing from the smallest to the largest,

Therefore, it is in addition to the function of rolling small pieces of stone, but also always ensure that the slurry which entered into the water pump ,can pass through the gap to reach to the soil warehouse, Therefore, it is in addition to the function of rolling small pieces of stone, but also always ensure that the mud can pass through the gap to reach the soil warehouse,And then discharged from the dredge pipe.

Also, because of the cutterhead movement,the soil chamber and the gap in soil chamber is constantly cyclic changing from the smallest to the maximum,Therefore, in addition to the function of rolling small pieces of stone, but also always ensure that the slurry can pass through the gap to reach the soil chamber,Thus ensuring that the boring machine is not only can work in the sand, even in the clay can work properly.

Under normal circumstances, the cutter rotates 4 - 5 revolutions per minute,When the cutter rotates one turn,The eccentric crushing action reaches 20 -23 times,Since the machine has these special constructions, so,its crushing capacity is the largest among all the other boring machines .The maximum size of the broken diameter can reach 40 -45% of the diameter of the jacking machine.Broken pebble strength can reach to 200Mpa.

The advantages of this boring machine are:

Features As Follows:

A :Pipe jacking machine, main jack, slurry circulation system and slurry and water separation device (DESANDMAN) as a set design.

B: The cutterhead with a tapered crusher , can crush gravel which is less than 30% of the outer diameter, and a shaft strength of 196Mpa (2000 kg/cm2).

C. The machine is suitable for a variety of soil conditions, such as clay, sand, gravel mixed pebble and soft rock.

D. Use the main cylinder installed on the track. A jacking length one time can reach more than 100m.

E The machine is controlled by one person on the ground.

F. It can control monitoring and direction on the control panel with the accuracy is high.

With RSG dual-beam target control system with ISEKI patent,Experienced operator can control the direction error within 10mm!

G. The use of the main jack can be uninterrupted separate jacking into a length of pipe

H. Slurry separation device DESANDMAN is a good sealing, flexible operation of the separation system and can save installation space.

This model is widely used nowadys .we have successful construction experience, technology is mature, reliable, less disturbance to soil . Eccentric crushed slurry balance pipe jacking machine is specially designed for gravel soil with high water content,So in particular to adapt to the construction of the base pipe jacking.

4.2 Flat layout, well layout and pipe layout

4.2.In the area of the working well, within the scope of the implementation of fully enclosed isolation and the necessary facilities are arranged : The ground command monitoring center, office ,warehouse , Power distribution room, Cold working room,Layout should be reasonable, clean environment, health, and a full-time staff to manage.

4.2.2 Site layout using 16t steam hanging, When the jacking machine approaches,will use 16t autocrane

4.2.3 When the Pipeline jacking, lifting equipment adopts a span length of 14m gantry crane( Lifting capacity of 30t),The guide rail and pipe jacking center line should be parallel laying, and symmetrical with the pipe center.

4.2.4 Well arrangement

The interior layout of the well is the rear back, the guide rail, the main roof oil cylinder, the oil pump power station, the Steel staircase and so on

4.3 Unearthed program

The slurry balanced pipe jacking machine is unearthed with fully automatic slurry conveying method ,The excavated soil is formed with slurry by mixing mud in the chamber, And then pump out by the mud pump ,high-speed drainage,At the top of the well, pile two desilters.Precipitated soil outward transport will be according to the requirement of civilized construction and the method of refuse disposal,Transported to the permanent pile solid place,Not to pollute environment along the road.

4.4 Jacking force calculation (See the hand-type mechanical pipe jacking)

4.5 Out of the hole solution

During the jacking process,In order to prevent the slurry pressure is too high flood into the working well,A single flanged wall steel casing is pre-installed in the entrance of the hole.For the installation of rubber sealing ring and sealing plate,Due to the jacking distance is long,Resulting in pipe surface and F-shaped steel ring, sand and other rubber seal on the inevitable wear and tear,will need to change the rubber seal ring frequently , Therefore, we add a rubber seal in the inside of the entrance of the hole ,When you need to replace the external rubber sealing flange,The rubber seal ring inside will prevents groundwater entering into the well.