High Chrome White Iron Wear Bars for G. E. T. Wear Protection

Hunan Hyster Material Technology Co., Ltd.- Type:Gouge Wear Part

- Application:Excavator, Loader. Bucket Lip, Crate

- Certification:ISO9001:2008

- Condition:New

- Name:Wear Bars

- Size:Swb 200, Swb 244, Swb 275,Swb 150,etc

Base Info

- Model NO.:SWB 200, SWB 244, SWB 275, SWB 150, ETC

- Material:High Chrome Cast Iron&Mild Steel

- Hardness:63HRC,700bhn

- Tensile Strength:630MPa Min

- Shearing Strength:250MPa Min

- Micro-Structure:Carbide+Martensite+Retained Austenite

- Place of Origin:China (Mainland)

- Applications:Wear Protection

- Products:High Chrome White Iron Wear Bars for G.E.T. Wear P

- Transport Package:Polywood Crate, Polywood Pallet, Water Proof Film

- Specification:High Grade

- Trademark:Domite, OEM, Hyster,

- Origin:Hunan, China

- HS Code:84314991

- Production Capacity:80tons,Month

Description

Basic Info.

Model NO. SWB 200, SWB 244, SWB 275, SWB 150, ETC Material High Chrome Cast Iron&Mild Steel Hardness 63HRC/700bhn Tensile Strength 630MPa Min Shearing Strength 250MPa Min Micro-Structure Carbide+Martensite+Retained Austenite Place of Origin China (Mainland) Applications Wear Protection Products High Chrome White Iron Wear Bars for G.E.T. Wear P Transport Package Polywood Crate, Polywood Pallet, Water Proof Film Specification High Grade Trademark Domite, OEM, Hyster, Origin Hunan, China HS Code 84314991 Production Capacity 80tons/MonthProduct Description

High Chrome White Iron Wear Bars for G.E.T. wear protectionDescription:L Hyster offer our clients a wide range of wear products and professional wear solutions. We also welcome custom made one off's and consumables. Wear Bars = high chrome cast iron( ASTM A 532, abrasion resistance) + mild steel backing plate( impact resistance)

1>Name: Shaped Wear Bar

2>Material: Laminated Wear Blocks combine very high wear resistant qualities of a high chrome cast iron (ASTM A532 15/3CrMo, 700 BHN - 63 HRc) with a weldable & high impact toughness mild steel plate.

3>Fuction: exceptionally resistant to impact and abrasion while retaining.

4>Advantage:

Better wear resistance performance,

Durable,

Cost effective,

Excellent quality,

Good service

5>Chemicals:

| C | Cr | Mn | Mo | Cu | P | Si | S | B,V,Nb |

| 2.5-3.5 | 15-18 | 0.5-1.5 | 0.5-2.5 | 0.5-1.0 | 0.02max | 0.5-1.0 | 0.02max | 0.1-0.5 |

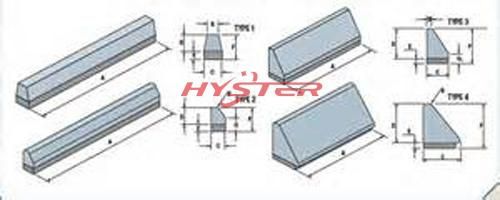

6>Types for Shaped Wear Bars

| Item NO. | Size(mm) | N.W. (kg) |

| SWB 200 | 200X13X30 | 0.8 |

| SWB 244 | 244X10X35 | 1.3 |

| SWB 202 | 202X10X35 | 1.1 |

| SWB 275 | 275X5X29 | 0.9 |

| SWB 150 | 150X10X70 | 2.4 |

| SWB 120 | 125X10X90 | 4.3 |

7>Some of our products and services:Wear plates, wear linersChocky bars and wear buttonsWear blocks, wear barsCustom made wear linersBucket repair and protectionFull Fabrication servicesSugar mill hammer tipsDrilling, milling or machiningCasting/Investment castingFast service and timely delivery