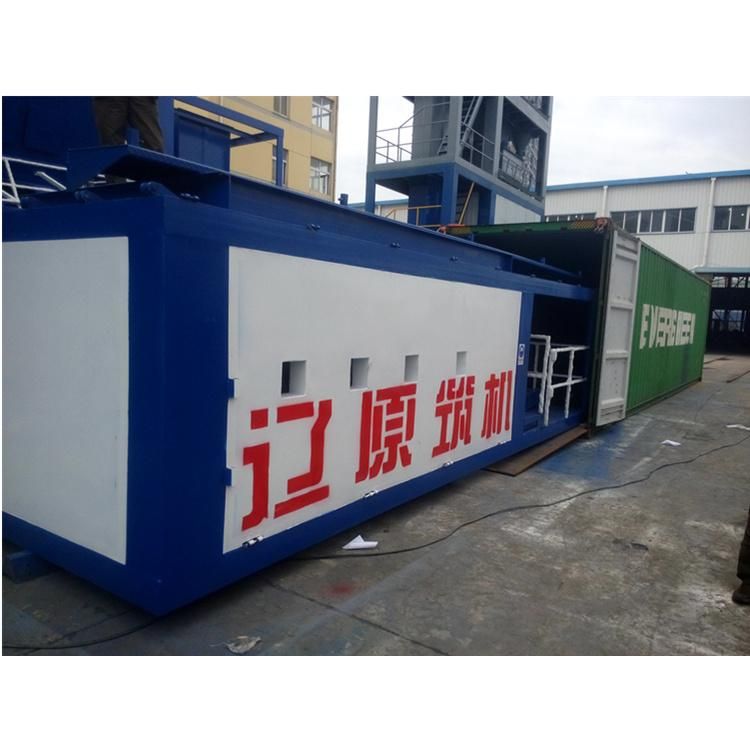

Liaoyuan 60 T/H 174HP Mdhb60 Mobile Asphalt Drum Plant

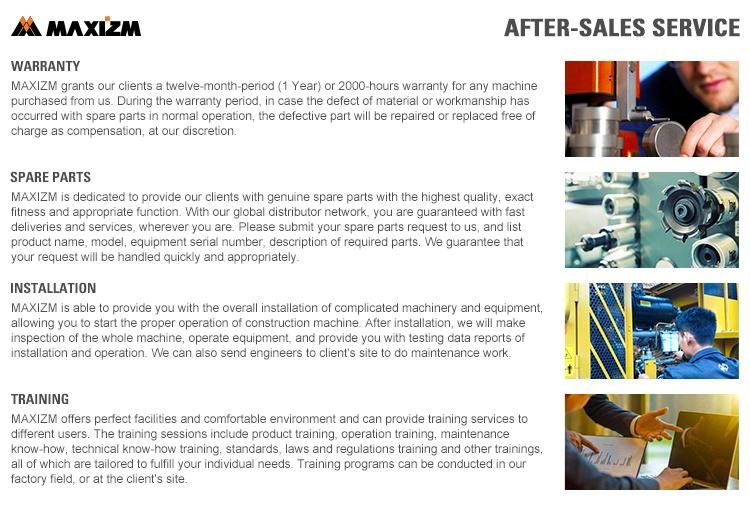

Maxizm Construction Machinery (Qingdao) Co., Ltd.- After-sales Service:1years

- Warranty:1years

- Type:Concrete Mixing Plant

- Shotcrete Type:Semi-Dry

- Machining Process:Hydraulic

- Structure:Cylinder Type

Base Info

- Model NO.:MDHB60

- Productivity:60 T,H

- Feeding Height:1370mm

- Vibrating Amplitude:1.0mm

- Certification:ISO9001: 2000

- Condition:New

- Color:White

- Product Name:Liaoyuan 60 T,H 174HP Mdhb60 Mobile Asphalt Drum P

- Application:High-Grade Asphalt Road Paving

- Product:Mini Mobile Asphalt Plant

- Keyword:Mobile Mini Asphalt Mixing Plant

- Service:Range

- Usage:Asphalt Mixture

- Key Words:Asphalt Mixng Plant

- Colors:Client′s Customized

- Function:Emulsified Asphalt

- Types:Automatic Batch

- Transport Package:Container or Nude Package

- Specification:Product Capacity: 60 t,h

- Trademark:Liaoyuan

- Origin:Henan

- Production Capacity:1000units,Year

Description

model

product capacity(t/h)

Engine power(kW)

fuel consumption(kg/t)

coal

oil

MDHB-20

20

40

10

5.5-7

MDHB-40

40

75

10-13

5.5-7

MDHB-60

60

128

10-13

5.5-7

MDHB-80

80

165

10-13

5.5-7

MDHB-100

100

200

10-13

5.5-7

1. Aggregate supplying system

1. Protective plates on both sides of the aggregate hoppers to avoid sundries getting into the aggregates and conveying belt;

2. To make the supplying smoother, vibrators are equipped below each hopper;

3. Adds grid plate at top of each hopper to buffer the shock from aggregates flow, meanwhile it screens oversize aggregates;

4. Conveying belt is protected by dustproof cover to reduce dust emission;

5. Adds belt cleaners and pinch rollers to make the aggregates supplying more fluent and accurate, besides, they also extend the belt durability;

6. Small vibrating screen is added between belts, to further screen oversize aggregates;

7. The supplying system has insufficient material alarm system, ensuring a safe and smooth production.

2. Drying system

1. Driving units have auto lubrication device, greatly reduces labor cost;

2. Different areas inside the drying drum have different blade configurations, which can handle aggregates in different processes;

3. The rolling rings and rollers are applying high strength wear-resisting material. Deviation preventing rollers for both rolling rings;

4. The cylinder adopts boiler steel and stainless steel skin, which gives it high temperature resistance and non-deformability;

5. The cylinder employs thermal insulating rock wool material that can maintain the temperature inside, reducing heat loss.

3. Bitumen supply system

The bitumen supply system is composed of bitumen tank, bitumen gear pump, pipes and bitumen spray tube. The gear pump is driven by the adjustable-speed motor and transfer the bitumen from bitumen tank to the drying drum for mixing process.

4. Dust Collecting System

The dust collecting system has two collecting levels, cyclone dust filter and water dust collector. The purified air flies up and gets discharged from the chimney, while the dust mud sinks in the sedimentation basin thanks to the gravity.

5. Finished product elevator

Finished product elevator has driving device, chains, chain wheels and a hopper. Its main function is to raise the finished product up to the storage silo.

6. Finished product silo

Finished product silo is used to temporarily store the asphalt mixture before truck loading. It mainly includes stand columns, storehouse, ladders, etc

7. Electrical control system

The Electrical control system which adopts centralized control technology, is composed by distribution cabinets, control room and other small auxiliaries. All the electrical components attached to the distribution cabinets are brand products, qualified and durable.

Product Advantages

MDHB series asphalt plant is mobile, continuous mixing plant, suitable for small and medium-sized road construction project required frequent relocation. It has advantages as the following:

1. Compact structure, less land footprint, could be located in a narrow or confined area;

2. The plant is consisting of four main modular; each with a mobile chassis, highly mobile, convenient for transportation and relocation;

3. Cold aggregate feeder with load cells and variable frequency motor; aggregate feeding is précised controlled;

4. Drying drum has functions of heating, drying and mixing, high energy efficiency ratio; optimized inner structure and external thermal insulation shell, fast heating speed and less heat loss;

5. Low initial investment and highly cost effective.