Flat Tank Cement Fly Ash Storage Silo Dry Mortar Silo for Concrete Batching Plant

HENAN SHENGMAO MACHINERY CO., LTD.- Type:Cement Silo

- Shotcrete Type:Dry

- Machining Process:Welded Molding Machine

- Productivity:35m²,h

- Feeding Height:1400mm

- Certification:ISO9001: 2000, CE

Base Info

- Condition:New

- Specification:30t 55t 70t 100t

- Trademark:shengmao

- Origin:China

- HS Code:7309000000

- Production Capacity:300

Description

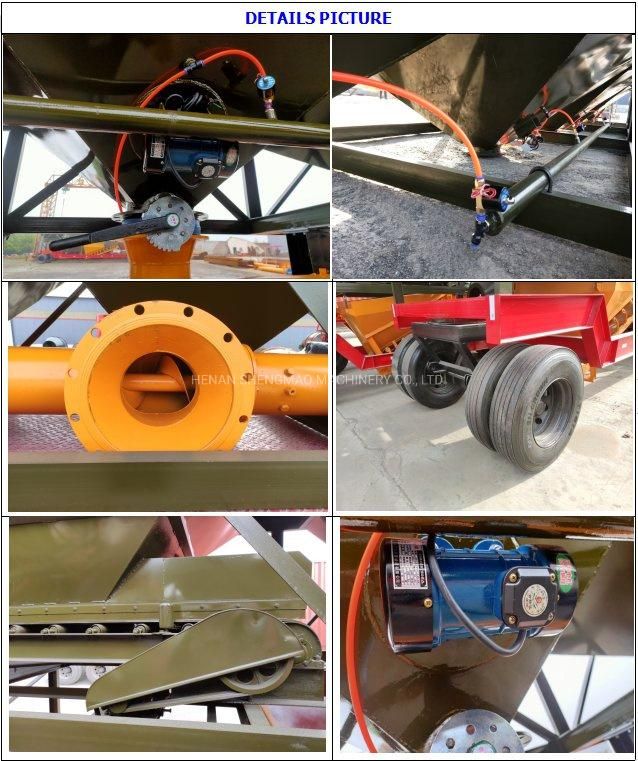

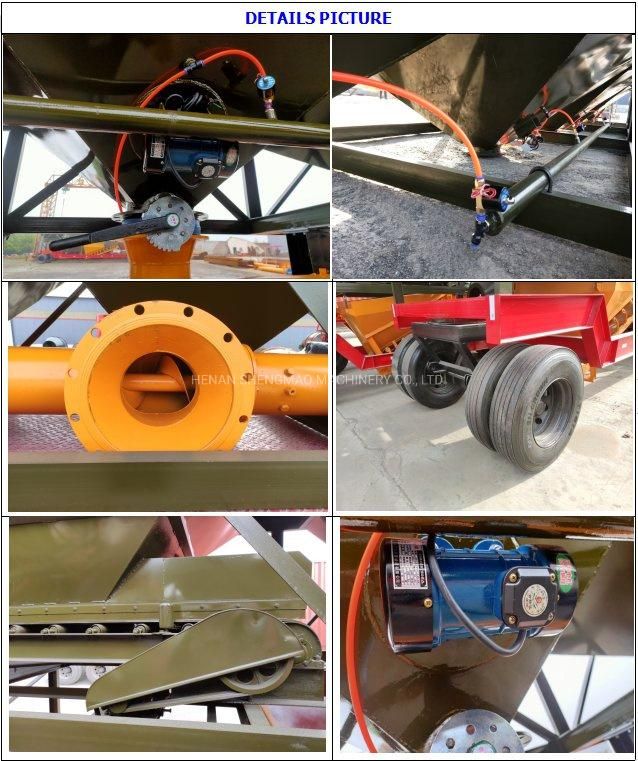

Silo top filter, safety valve, level indicator, flow promotion device, inside and outside ladders, butterfly valve, vibratingmotor.

More Pictures

Stationary type

Mobile type

Welding workshop

Transportation

Our project

Horizontal cement silo to Canada

Horizontal Cement Silo to Italy

Horizontal Cement Silo to Italy

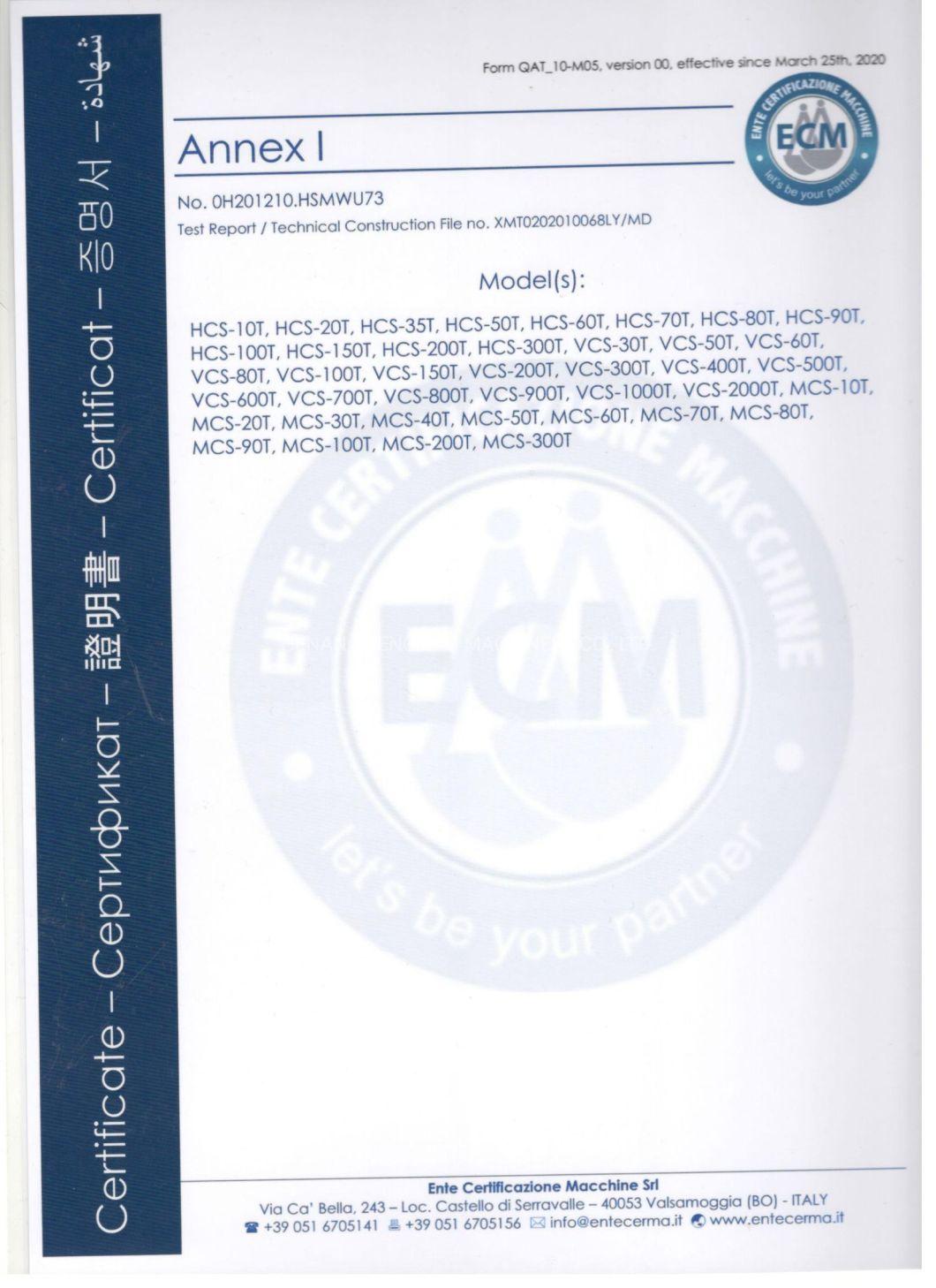

CE CERTIFICATE

CE CERTIFICATE

Our Service

Pre-sale Service

1 Answering customers' questions, helping customers choose the most suitable machines;

2.Making design drawings as per customers' requirements;

3. Providing quotations.

In-sale Service

1. Strictly control all prodedures from raw materials sourcing to pre-assembly to ensure product quality;

2. Regularly updating production production progress to clients;

3. After the production is completed, pre-assembly and test running will be carried out to make sure our machine works well;

4. Proper packing to minimize the risk that the machines are damaged during transportation;

5. Foundation drawing will be provided for clients to make foundation in advance.

After-sale Service

1. Providing 7 * 24 hours online after-sales service every week

2. Providing related certificates, customs clearance documents, operation and maintenance instructions, installation videos, etc.

3. Arranging engineers to go to client's job site. The engineers will help clients with the machine installation, machine

test-running and operators training etc.

4. Spare parts supply;

5. Job site visiting every year.

More Pictures

Stationary type

Mobile type

Welding workshop

Transportation

Our project

Horizontal cement silo to Canada

Horizontal Cement Silo to Italy

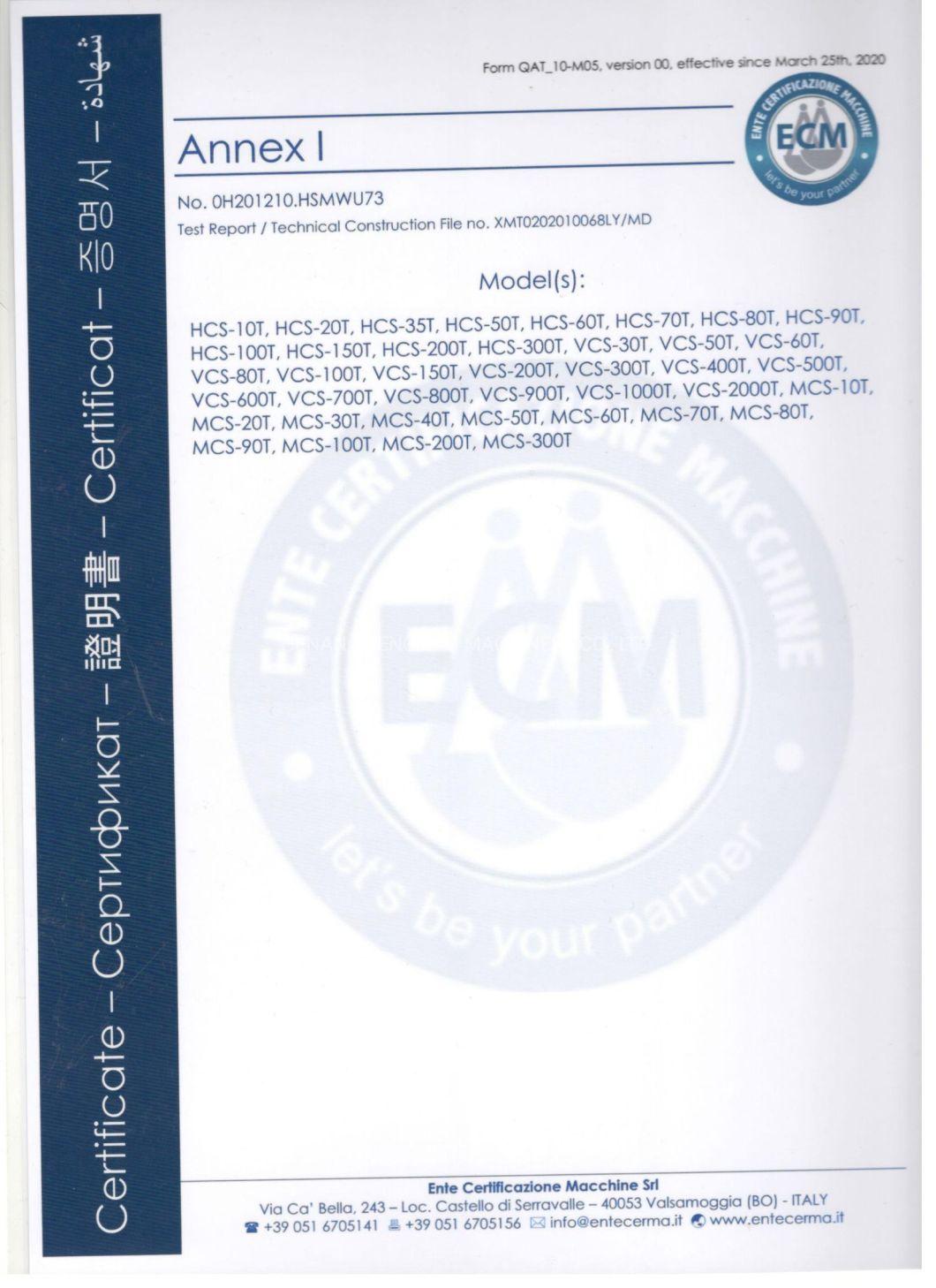

Horizontal Cement Silo to Italy  CE CERTIFICATE

CE CERTIFICATE

Our Service

Pre-sale Service

1 Answering customers' questions, helping customers choose the most suitable machines;

2.Making design drawings as per customers' requirements;

3. Providing quotations.

In-sale Service

1. Strictly control all prodedures from raw materials sourcing to pre-assembly to ensure product quality;

2. Regularly updating production production progress to clients;

3. After the production is completed, pre-assembly and test running will be carried out to make sure our machine works well;

4. Proper packing to minimize the risk that the machines are damaged during transportation;

5. Foundation drawing will be provided for clients to make foundation in advance.

After-sale Service

1. Providing 7 * 24 hours online after-sales service every week

2. Providing related certificates, customs clearance documents, operation and maintenance instructions, installation videos, etc.

3. Arranging engineers to go to client's job site. The engineers will help clients with the machine installation, machine

test-running and operators training etc.

4. Spare parts supply;

5. Job site visiting every year.