4ton Underground Scooptram Load Haul Dump Loaders

Qingdao Tunnel Mine Equipment Technology Co., Ltd.Base Info

- Model NO.:TL204W

- Production Capacity:150 Units,Year

Description

Basic Info.

Model NO. TL204W Production Capacity 150 Units/YearProduct Description

TL203W

Technical Specification:

Brief Introduction:

TL203W is a high-efficiency LHD designed for narrow tunnels.The fully loaded bucket size is 2m3.The load capacity is 4-4.5t.Reasonable system layout, quite compact body design,small turning radius,powerful drive,high ore removal efficiency.We've made many technical improvements on power system, drivetrain system and control system, therefore this model is quite suitable for ore removal from small size narrow tunnel mines.

Design Optimization:

- High efficiency of ore removal

- Under condition of stress optimization of boom structure,without any alteration of vehicle's overall dimensions,adjustment has been made for boom material and welding technology, so to make the stress more rationalized.

- Bucket optimization, without any alteration of vehicle's overall dimensions, has increased the bucket's loading efficiency.

- Flexible and convenient operation

- Hydraulic control of working and steering make the working and steering operations more convenient and flexible.

- Electrical controlled transmission and electrical control handle shifting make controllability of shifting increased.

- Powered by air-cooled Deutz diesel engine F6L914 with more powerful drive.

- 32000 series transmission and C270 series torque inverter, highly increase power match.

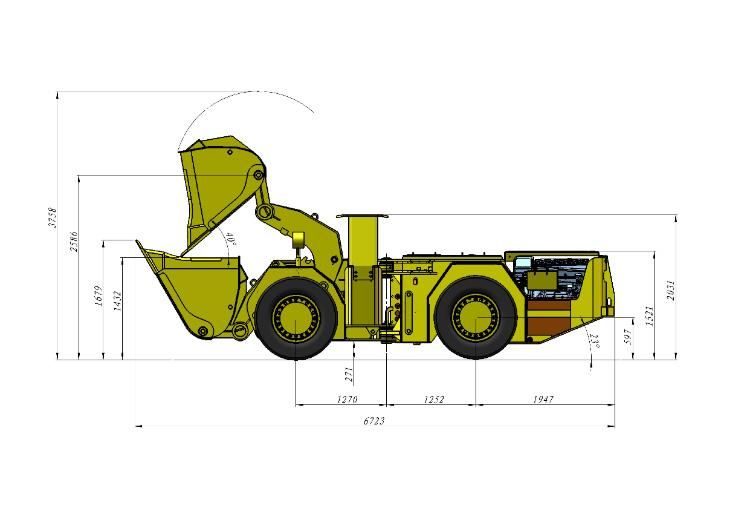

- Outer Dimensions:

- Weight Parameter:

| Loading capacity | 3600Kg |

| Vehicle empty load | 1 2500Kg |

| Operation weight when fully loaded | 161000Kg |

- Working Device System:

| Hoisting cylinder | Dia.80mm | 1 unit |

| Lifting time | 3.8s | |

| Dumping cylinder | Dia.80mm | 1 unit |

| Dumping time | 5.6s |

- Transmission

- Torque Converter

- Axle

Rear axle:Heavy-duty rigidity axle, Dana 14D or D71 ,with no-spin differential installed internally. With big reduction ratio and high load bearing strength.

Axle braking:Adopting international used POSI-STOP brake,spring applies the brake,hydraulic release,to ensure the safe and reliable performance of brake.

Brake cooling of axle:Hydraulic oil

forced cooling.

- Braking System

- Electrical System

Negative wire is connected in switch box to protect the stability of electrical wiring.

- Tyre

- Control System

The cabin comply with the ISO ROPS/FOPS certifications of underground special vehicles.

- Hydraulic system

Working system applies duplex pump, while braking system uses single pump, both of them are of Parker brand.

- Oil Tank

Volume of hydraulic oil tank is 144L

- Steering System

- Exhaust System

- Others

(Automatic centralized system for option)

Equip with fire extinguisher system

(Automatic fire extinguisher system for option)