Mini PC20 Excavator Track Bolt and Nut for Undercarriage Parts

QUANZHOU DINGTAI ENGINEERING MACHINERY CO., LTD.- Application:Excavator

- Certification:CE, ISO9001: 2000

- Condition:New

- Material:50mn

- Colors:Black or Yellow

- Technique:Forging & Casting

Base Info

- Model NO.:PC20

- Warranty Time:2000 Hours

- MOQ:5PCS

- Delivery Time:Within 30 Days After Contract Established

- Package:Fumigate Seaworthy Packing

- Product Name:PC20 Excavator Track Bolt and Nut

- Transport Package:Wood Pallet

- Specification:PC200

- Trademark:Dingtai

- Origin:Fujian

- HS Code:84314999

- Production Capacity:5000 PCS Per Month

Description

Basic Info.

Model NO. PC20 Warranty Time 2000 Hours MOQ 5PCS Delivery Time Within 30 Days After Contract Established Package Fumigate Seaworthy Packing Product Name PC20 Excavator Track Bolt and Nut Transport Package Wood Pallet Specification PC200 Trademark Dingtai Origin Fujian HS Code 84314999 Production Capacity 5000 PCS Per MonthProduct Description

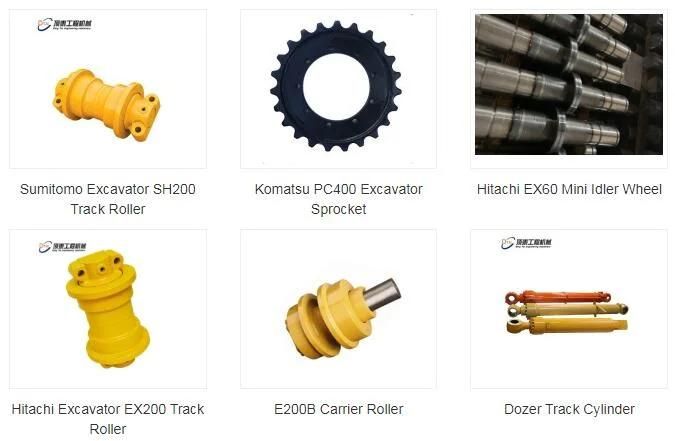

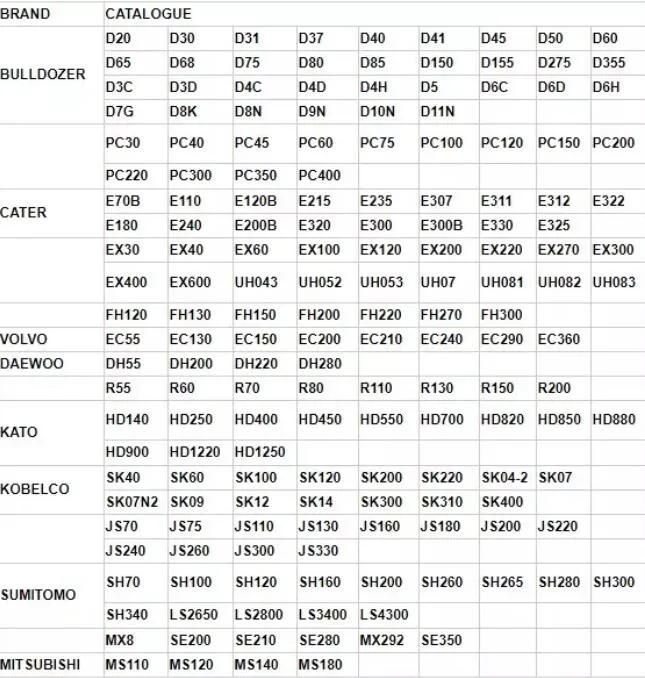

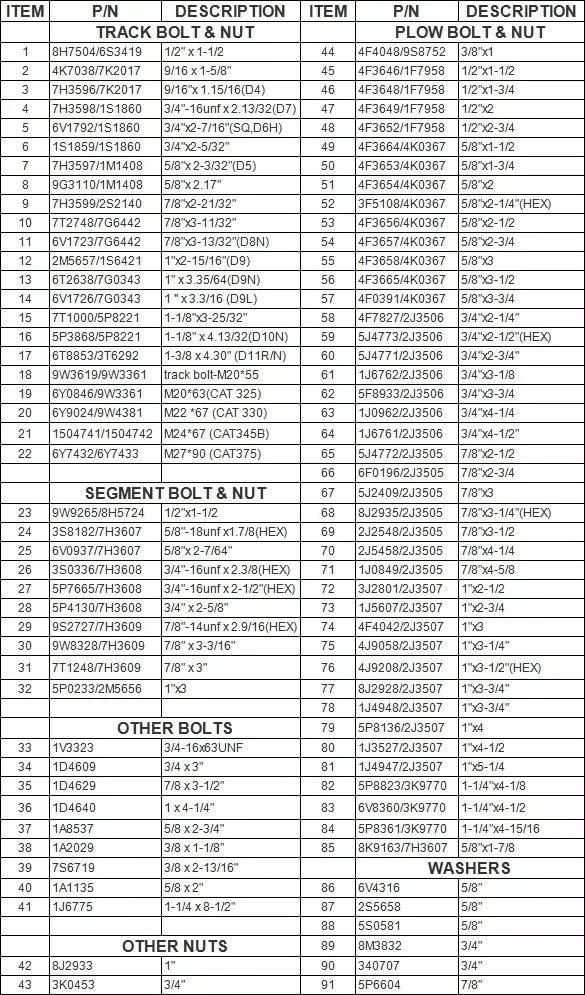

Products Specifications:Bolt And Nut For Roller Segment Sprocket Bolt

Bolt and Nut for track roller

Bolt and Nut for Carrier roller

Bolt and Nut for sprocket

1.Information products

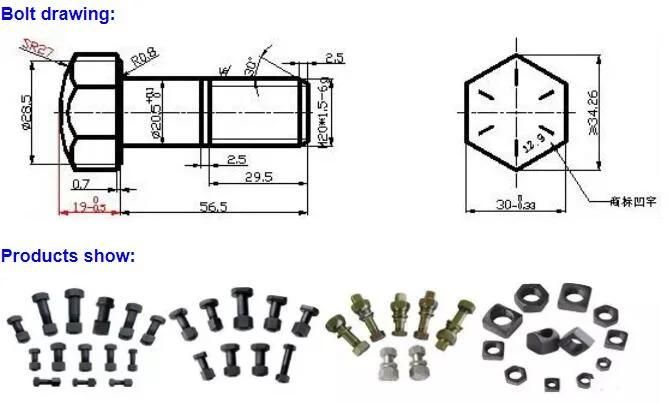

Length: 1"-20"

Dia:1/8"-1 1/2"

Grade: 5 & 8

Material: 45Cr, 35GrMo,42GrMo

Standard: ANSI, DIN, BS, AS, etc.

2.Design / Structure / Details Pics

Advantages / Features

1). Materials:

Our company has purchased steel from several large steel groups , such as Hangzhou Steel Mill,

Shanghai Bashan Steel Mill, Beijing Shrugging Steel Mill whose steel have good mechanical properties

and stability of chemical component. it keep the bolt to be of high strength

2). Manufacture Procession

First, we have our own High-precision Digital Machining center for mould making in special Mould

Workshop, excellent mould make product beautiful appearance and its size accurately.

The second, we adopt blasting procession, removing Oxidation surface , make the surface to be

bright and clean and uniform and beautiful.

The third, in heat treatment: We use the Controlled-atmosphere Automatic heat treatment Furnace,

we also have four mesh belt convey furnaces, Can deal with the products in different sizes keeping the

non-oxidation surface

3). The all process quality control:

The quality control is strictly performed from buying raw materials in warehouse to different machining

procession and to final packing. We have Magnetic Powder Detector, Material Testing Machine,

Metallographic Microscope, such testing instruments, guarantee product high quality and beautiful

appearance.

4). Our production capacity

Single bolts, every month can produce 1.7 million bolts. Now we buy a Full Automatic Cool-forging

Machine.this greatly enhances our production capacity with more quality and more beautiful appearance.

Bolts & nuts model as follow

About US:

We are located in Quanzhou Fujian. We are a professional manufacturer that is specialized in producing High Quality Parts for Excavator, Bulldozer and other construction machines.

To ensure product quality, we are strict in quality control, from raw material, design, technology, manufacturing for the entire process of detection.

Contact US

Hot Tags: bolt for track roller, manufacturers, suppliers, factory, wholesale, customized, price, discount, bulk, OEM