2021 New Design 9-6000t Corn Maize Silo Steel Grain Silo with Conic Base

Jiangsu Liangyou Zhengda Co., Ltd.- Type:Silo

- Machining Process:Weld and Assemble

- Structure:Spiral Type

- Certification:ISO9001: 2000, CE, SGS

- Condition:New

- Material:Galvanized Steel Silo

Base Info

- Model NO.:FDSP series

- Diameter:4-25m

- Size:300-10000m3

- Capacity:54000t

- Delivery Detail:30-90 Days

- Transport Package:International Standard Package

- Specification:CE ISO SGS

- Trademark:FDSP

- Origin:Jiangsu, China (Mainland)

- HS Code:8436100000

- Production Capacity:30-15000t

Description

Basic Info.

Model NO. FDSP series Diameter 4-25m Size 300-10000m3 Capacity 54000t Delivery Detail 30-90 Days Transport Package International Standard Package Specification CE ISO SGS Trademark FDSP Origin Jiangsu, China (Mainland) HS Code 8436100000 Production Capacity 30-15000tProduct Description

2021 New Design 9-6000t Corn Maize Silo Steel Grain Silo with Conic Base

Jiangsu Liangyou Zhengda Co., Ltd is a professional enterprise engaged in steel silo equipment and storage engineering technology research, development, design, manufacturing and related products sales & service. Steel silo engineering could be applied in: food industry, feed industry, oil industry, building materials industry, brewing industry and port industry. FDSP is specialized in design, manufacture, installation for both domestic and foreign helix silo and bolt silo project.

Introduction about bolt silo:

fabricated by good quality hot-dip galvanized steel sheet(mass of Zn coat could be: 275g/m2,350g/m2,450g/m2), adopt full automatic corrugated plate production line. The diameter of bolt silo could varied from φ2.75m toφ27.5m, height of straight part could varied from 1.12m to 20.16m, the storage volume could varied from 11m³ to 13333m³.

Temperature measuring system, ventilation system, indicator level system, circulation fumigation system inside the silo could be optional according to customer's need.

Based on the carried material, the silo could be divided into: maize steel silo, soybean steel silo, wheat steel silo, barley steel silo, sorghum steel silo, soybean meal steel silo, sawdust steel silo, biomass pellet steel silo. Also we can customized flour steel silo, cement steel silo, building materials steel silo;

Based on the hopper type, the silo could be divided into: concrete flat bottom steel silo, concrete cone hopper steel silo, steel structure support steel silo(single silo capacity should less than 1500T).

Project instruction:

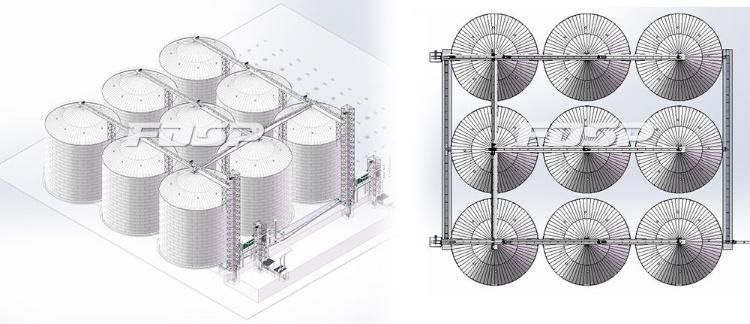

This project is 9-6000T maize steel silo storage project, the technological characteristics are as follows:

1- The main materials in silo are maize, the silo type is the bolt silo with diameter ¢22m, the height of the straight part is 20.16m, and the base is flat bottom, the discharge is using sweeping auger with 100TPH capacity.

2- The main process: unloading-cleaning-storage-silo changing- discharging

1) unloading process is double side loading, the grizzly can carry the truck, two sided of dumping hoper is equipped with de-dusting system to improve the working condition.

2) cleaning process is equipped with double drum cleaner and tubular magnet with large capacity 200TPH

3)storage process: the capacity for inlet is 200TPH, there is temperature measuring and ventilation system inside the silo which could control the grain condition.

4)silo changing process: the capacity of changing is 100TPH,using heavy belt conveyor.

3. Features of the engineering process design:

1)in this process, consider the large storage capacity(54000T), quick unloading(the general inlet speed 400TPH), so we use double unloading system so as to loading by two trucks at same time.

(2) When design the silo, the ventilation screen is designed to be detachable and easy to replace, so as to keep the air duct unobstructed and the good ventilation effect, effectively control the grain situation in the silo;

3) the silo changing system is used in the process, the material in the silo could transport to any other silo.

4) double direction heavy belt conveyor is used on the bottom of silo which save the equipment and power, the silo changing and discharging could be made by one equipment.

4. Other instructions:

For different projects and different customer requirements, the process will be also different, the following could be options during the process design:

(1) cleaning system (this part can be removed if the raw materials are clean);

(2) ventilation and temperature measuring system (if the raw materials are relatively dry, and the storage time in the silo is less than 7 days in winter and less than 4 days in summer, this part can be removed);

(3) the silo changing system (if the storage time in the silo exceeds 60 days in winter and 30 days in summer, the warehouse changing system shall be considered);

(4)As the single silo capacity is large than 5000T, So we suggest to use bolt silo not helix silo.

Project Show

FDSP Workshop

About FDSP