Flexible Steering Rvds4.5h Full Hydraulic Vibratory Oscillatory Road Roller

Maxizm Construction Machinery (Qingdao) Co., Ltd.- Type:Road Roller

- Working Method:Steel Wheel

- Axle:Biaxial Dual-Drum

- Grinding Wheel Type:Tire Grind

- Compaction Depth:40cm

- Engine Type:Petrol Engine

Base Info

- Model NO.:ZL50GN,LW300KN,LW300FN,QY50KA

- Travel Speed:40cm,s

- Centrifugal Force:40KN

- Certification:EPA, CS, CE, RoHS, ISO 9001:2000, ISO 9001:2008

- Condition:New

- Transport Package:Nude

- Specification:2009kN. m

- Trademark:SHANTUI

- Origin:China

- HS Code:8429401100

- Production Capacity:1000000pieces,Year

Description

Basic Info.

Model NO. ZL50GN/LW300KN/LW300FN/QY50KA Travel Speed 40cm/s Centrifugal Force 40KN Certification EPA, CS, CE, RoHS, ISO 9001:2000, ISO 9001:2008 Condition New Transport Package Nude Specification 2009kN. m Trademark SHANTUI Origin China HS Code 8429401100 Production Capacity 1000000pieces/YearProduct Description

SHANTUI 20Ton Road Roller Compactor Garbage compactor SR23MR

Bella Song/Sales Director

OVERALL WEIGHT

23000kg

ENGINE POWER

With 162kW/2200rpm, this engine conforms to China-III emission regulation.

COMPACTING WIDTH

3090mm

Operating cost

♣The proprietary match technology and the optimal power curve can achieve high operating efficiency and reasonable fuel economy and reduce the composite fuel consumption by 5%~8%.

♣The core electric and hydraulic parts feature high reliability to reduce the malfunction downtime.

♣ High value maintenance

High maintenance convenience

♣The lubricating points are centrally arranged and the rear hood adopts combination openable structure to improve the repair and maintenance convenience.

♣The connection between blade and front frame adopts unique seat bolted cover and ball joint to ease the assembling, which can be easily replaced if worn.

Working performance

♣The installed Weichai China-III electronic control engine can maintain the machine under best working status with strong power to ensure the compacting quality and high efficiency and energy-saving.

♣The hydro-mechanically driven power drive system is professionally designed and precisely manufactured specially for severe waste treatment environment and provide higher productivity.

♣ The high capacity blade can bulldoze the waste during the compacting to improve the operating efficiency.

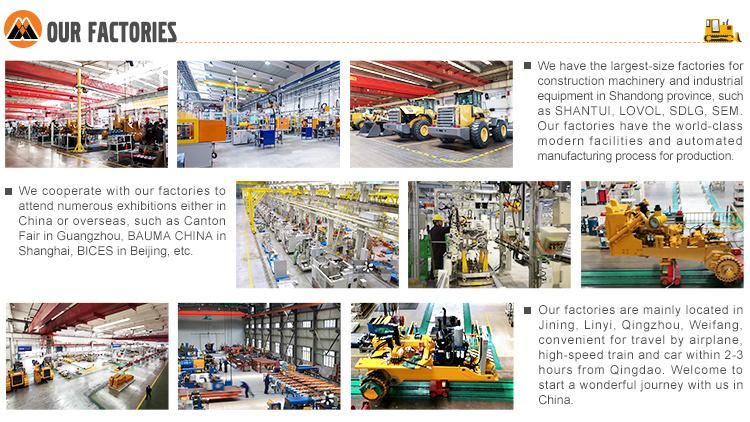

♣The professionally designed compacting drum guarantees the effective compacting and crushing of the waste. The compacting teeth are made of corrosion-resistant and wear-resistant material to prolong the life of compacting drum.