Mobile Cement Concrete Batch Mixing Plant 75m3/H for Road Construction and Building Construction

HENAN SHENGMAO MACHINERY CO., LTD.- Type:Concrete Mixing Plant

- Shotcrete Type:Wet

- Machining Process:Concrete Wet Mix

- Structure:Rotor Type

- Productivity:30m3,H

- Certification:ISO9001: 2000, CE

Base Info

- Condition:New

- Concrete Mixer:Jzm1500

- Aggregate Batcher:PLD2400

- Aggregate Feeding Mode:Belt Conveyor

- Max. Aggregate Size (mm):60,80

- Discharging Height (M):1.3

- Total Power (Kw):67.5

- Control System:Computer

- Transport Package:Container Transportation

- Trademark:shengmao

- Origin:China

- HS Code:8474310000

- Production Capacity:100

Description

26 T

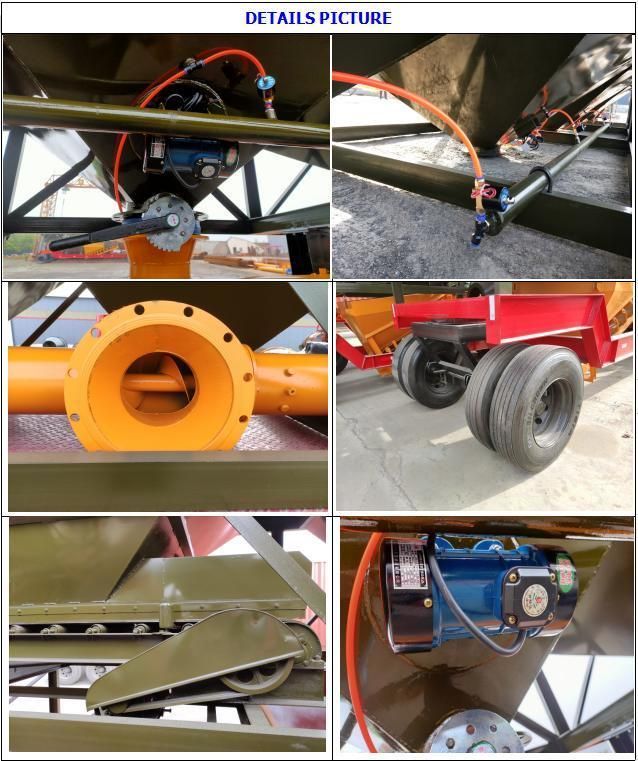

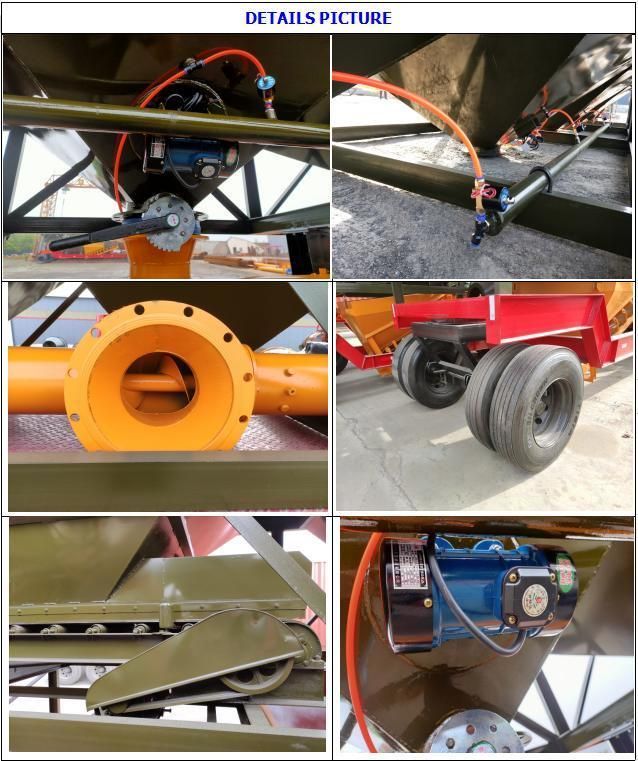

Detailed Images

Packing&Shipping:

Our Project:

Our service:

Pre-sale Service

1 Answering customers' questions, helping customers choose the most suitable machines;

2.Making design drawings as per customers' requirements;

3. Providing quotations.

In-sale Service

1. Strictly control all prodedures from raw materials sourcing to pre-assembly to ensure product quality;

2. Regularly updating production production progress to clients;

3. After the production is completed, pre-assembly and test running will be carried out to make sure our machine works well;

4. Proper packing to minimize the risk that the machines are damaged during transportation;

5. Foundation drawing will be provided for clients to make foundation in advance.

After-sale Service

1. Providing 7 * 24 hours online after-sales service every week

2. Providing related certificates, customs clearance documents, operation and maintenance instructions, installation videos, etc.

3. Arranging engineers to go to client's job site. The engineers will help clients with the machine installation, machine

test-running and operators training etc.

4. Spare parts supply;

5. Job site visiting every year.

Detailed Images

Packing&Shipping:

Our Project:

Our service:

Pre-sale Service

1 Answering customers' questions, helping customers choose the most suitable machines;

2.Making design drawings as per customers' requirements;

3. Providing quotations.

In-sale Service

1. Strictly control all prodedures from raw materials sourcing to pre-assembly to ensure product quality;

2. Regularly updating production production progress to clients;

3. After the production is completed, pre-assembly and test running will be carried out to make sure our machine works well;

4. Proper packing to minimize the risk that the machines are damaged during transportation;

5. Foundation drawing will be provided for clients to make foundation in advance.

After-sale Service

1. Providing 7 * 24 hours online after-sales service every week

2. Providing related certificates, customs clearance documents, operation and maintenance instructions, installation videos, etc.

3. Arranging engineers to go to client's job site. The engineers will help clients with the machine installation, machine

test-running and operators training etc.

4. Spare parts supply;

5. Job site visiting every year.