ISO-Approved Excavator Long Reach Arm for All Excavator Scope 15.38 Meter

Heng Wei Machine (Zhangzhou)Co., Ltd.- Warranty:180 Day

- Type:Crawler Excavator

- Usage:Special Excavator, Mining Excavator, GM Excavator

- Transmission:Hydraulic Transmission

- Drive Type:Internal Combustion Drive

- Bucket Capacity:0.5~1.0m³

Base Info

- Size:Large-Scale

- Certification:ISO9001: 2015

- Condition:New

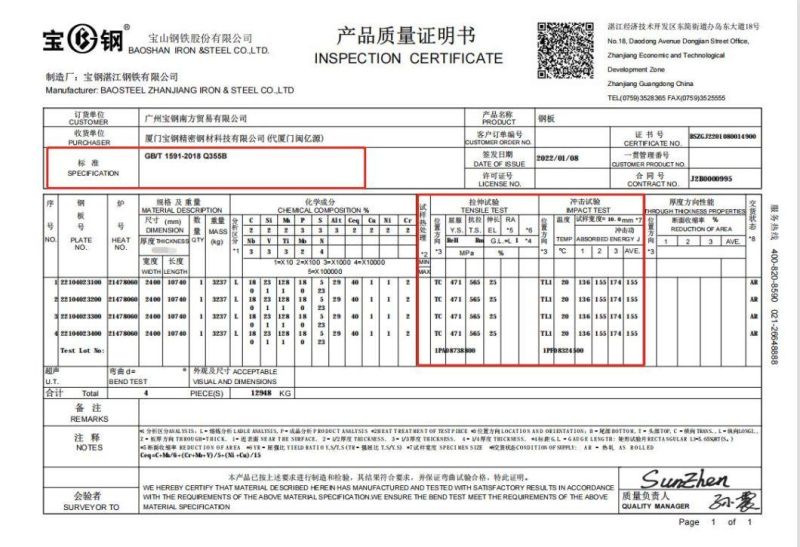

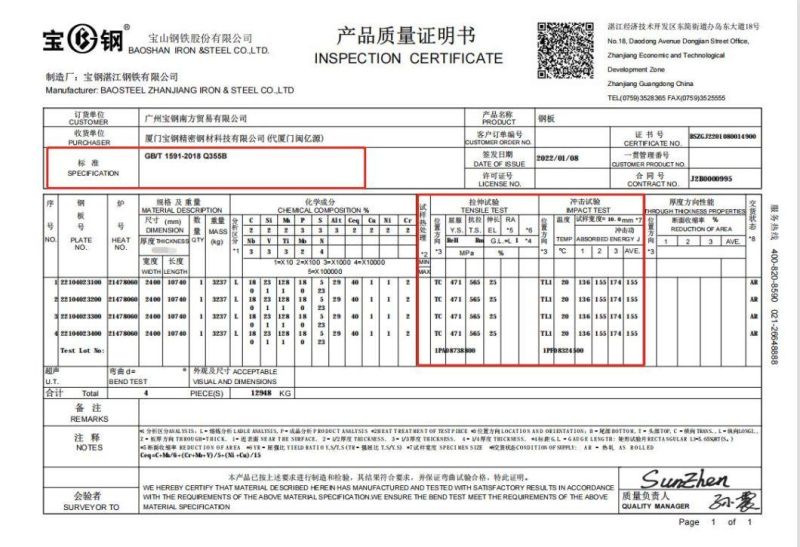

- Material:Q355b

- Long Boom+Long Arm(Meter):9.15+6.10

- Transport Package:Bubble Film

- Origin:Zhangzhou City, Fujian Province

- HS Code:843149

- Production Capacity:1000set,Year

Description

40-47T Total length mm 15200 18000 18000 20000 22000 20000 22000 24000 Max digging radius mm 15000 17300 17300 19200 21000 19200 21000 23000 Max cut depth mm 10300 12500 12600 14500 16000 14500 16000 17000 Max cut depth vertically mm 9500 11600 11700 13600 15200 13600 15200 16200 Max cut height mm 12600 15300 15300 17300 18500 16200 17500 18750 Max unloading height mm 10300 13000 13000 15000 16000 14000 15000 16000 Min rotate radius mm 4750 5100 5100 6200 6200 6200 7750 7750 Boom length mm 9100 10500 10500 11500 12500 11500 12500 13350 Stick length mm 6100 7500 7500 8500 9500 8500 9500 10650 Stick max cut force(ISO) KN 83 65 118 95 80 170 139 109 Bucket max cut force(ISO) KN 150 99 153 153 153 153 153 153 Bucket capacity m3 0.5 0.4 1.2 0.7 0.5 1 0.8 0.7 Bucket rotate degree deg 170 170 170 170 170 170 170 170 Folding length mm 13000 14500 15000 16000 17000 16000 17000 18000 Folding heigtht mm 3050 3100 3300 3350 3400 3450 3480 3500 Extra Counter weight T 1 3.5 4 5 6 5 6 8

2.Material processing

2.Material processing

Use a plasma cutter to ensure part flatness

Use a plasma cutter to ensure part flatness

3.Internal vie

Spaced by vertical and horizontal reinforcement plate at regular interval4.Product making

Welding

A.) Welded with mixed gas between argon and carbon dioxide. Argon content:80%.Carbon dioxide content:20%.

B.) Welded by auto-welding machine .

Sandblasting

A.) The surface of the workpiece can obtain a certain degree of cleanliness and different roughness, so that the mechanical properties of the workpiece surface are improved, thus improving the fatigue resistance of the workpiece, increasing the adhesion between it and the coating, and prolonging the coating film. Durability, also good for paint leveling and decoration.

5.Product packaging and Shipping

6.Company Services

6.Company Services

1, Long reach boom are use for dredging rivers port construction, railway construction and groundwork construction, with high extensive operation scope, high efficiency and high security.

2, Our company was founded in 2008 with more than 10 years of experience, production line engineers have more than 10 years of data and experience for all brands of excavators designed and customized long range booms.

3, Applicable for all the excavator model,OEM service is also available.

4, Advanced manufacturing process, Technique is in the line with global standards.

5, We have all the installation dimensions of most excavator, we can customize this long reach boom for your excavator.

6, Before welding, we have use big edge milling machine mill(taper process) the edge of the sheet. So the welding can go to the internal of the steel-sheet and make the structure have higher performance. Also the inside have strength plate make it more stronger.

7, If necessary, extra pipeline can be added to suit to some extra application.

8, Stick cylinder of the long boom, can use your original stick cylinder to save the cost, if you need the stick cylinder, we also can prepare for you.

9, Some parts can be consolidated using thicker plate or overlapping another plate for heavy-duty application.

10, Welding is protective-gas welding, the protective gas is 80% Argon and 20% CO2 mixed. This is golden standard for protective gas.

11, Before welding, we have use big edge milling machine mill the edge of the sheet. So the welding can go to the internal of the steel-sheet and make the structure have higher performance.

12 .We can customize the arm for all kinds of excavator as per your request. Just let me know your request.

13. If you need, some parts can be consolidated using thicker plate or overlapping another plate for heavy-duty application, just let me know.

14. Not make the bucket for this extender arm as customer request. But if you need us prepare the bucket for you, that's ok.

2.Material processing

2.Material processing

Use a plasma cutter to ensure part flatness

Use a plasma cutter to ensure part flatness3.Internal vie

Spaced by vertical and horizontal reinforcement plate at regular interval4.Product making

Welding

A.) Welded with mixed gas between argon and carbon dioxide. Argon content:80%.Carbon dioxide content:20%.

B.) Welded by auto-welding machine .

Sandblasting

A.) The surface of the workpiece can obtain a certain degree of cleanliness and different roughness, so that the mechanical properties of the workpiece surface are improved, thus improving the fatigue resistance of the workpiece, increasing the adhesion between it and the coating, and prolonging the coating film. Durability, also good for paint leveling and decoration.

5.Product packaging and Shipping

6.Company Services

6.Company Services1, Long reach boom are use for dredging rivers port construction, railway construction and groundwork construction, with high extensive operation scope, high efficiency and high security.

2, Our company was founded in 2008 with more than 10 years of experience, production line engineers have more than 10 years of data and experience for all brands of excavators designed and customized long range booms.

3, Applicable for all the excavator model,OEM service is also available.

4, Advanced manufacturing process, Technique is in the line with global standards.

5, We have all the installation dimensions of most excavator, we can customize this long reach boom for your excavator.

6, Before welding, we have use big edge milling machine mill(taper process) the edge of the sheet. So the welding can go to the internal of the steel-sheet and make the structure have higher performance. Also the inside have strength plate make it more stronger.

7, If necessary, extra pipeline can be added to suit to some extra application.

8, Stick cylinder of the long boom, can use your original stick cylinder to save the cost, if you need the stick cylinder, we also can prepare for you.

9, Some parts can be consolidated using thicker plate or overlapping another plate for heavy-duty application.

10, Welding is protective-gas welding, the protective gas is 80% Argon and 20% CO2 mixed. This is golden standard for protective gas.

11, Before welding, we have use big edge milling machine mill the edge of the sheet. So the welding can go to the internal of the steel-sheet and make the structure have higher performance.

12 .We can customize the arm for all kinds of excavator as per your request. Just let me know your request.

13. If you need, some parts can be consolidated using thicker plate or overlapping another plate for heavy-duty application, just let me know.

14. Not make the bucket for this extender arm as customer request. But if you need us prepare the bucket for you, that's ok.

| MODEL | LDB120 | LDB200-1 | LDB200-2 | LDB300 | LDB350-1 | LDB350-2 | LDB450 |

| boom length(mm) | 7100 | 8220 | 10000 | 10000 | 11000 | 12000 | 13000 |

| arm length ( mm) | 5900 | 7160 | 8000 | 8000 | 9000 | 10000 | 11000 |

| Weight(kg) | 3000 | 4000 | 4200 | 5200 | 6000 | 6500 | 7000 |

| Max dig depth(mm) | 9000 | 11340 | 12200 | 12200 | 14500 | 16100 | 18000 |

| Max. extensive scope(mm) | 12500 | 15100 | 17600 | 17600 | 19600 | 21600 | 23600 |

| Max. dig height(mm) | 11300 | 12510 | 13500 | 13720 | 14920 | 16100 | 17300 |

| folding height(mm) | 2900 | 2980 | 3040 | 3210 | 3210 | 3400 | 3400 |

| bucket capacity(m3) | 0.3 | 0.5 | 0.4 | 0.4 | 0.5 | 0.6 | 0.6 |

| Suit Excavator tonnage(ton) | 12 | 20 | 20 | 30 | 35 | 35 | 45 |