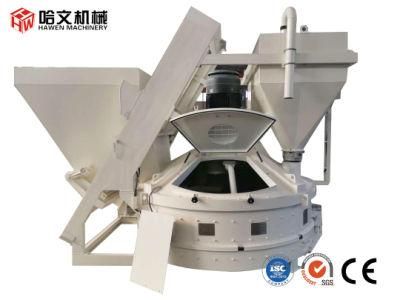

High Speed Planetary Mixer for Block Making Production Line

Quanzhou Hawen Machinery Co., Ltd.- After-sales Service:Engineer Available to Abroad

- Warranty:One Year After Installation

- Type:Concrete Mixer

- Shotcrete Type:Wet

- Machining Process:Hydraulic

- Structure:Cylinder Type

Base Info

- Model NO.:MP1000

- Productivity:75m²,h

- Feeding Height:1400mm

- Vibrating Amplitude:2.4mm

- Certification:CE

- Condition:New

- Color:White

- Loading System:Bucket Hoist or Conveyor Belt

- Main Motor Power:30kw

- Control System:Automatic

- Side Scraper:1

- Power:15-55kw According to Size of Mixer

- Input Capacity:500-2000L

- Discharging Quantity:800-3000kg

- Discharging Height:1500 or 3800mm

- Transport Package:Standard Ocean Packing

- Trademark:HAWEN

- Origin:China

- HS Code:847431000

- Production Capacity:150 Sets, Year

Description

Planetary Concrete Mixer Technical Data Item Unit MP330 MP500 MP750 MP1000 MP1500 Rated Feeding Volume L 500 750 1125 1500 2250 Rated discharging Volume L 330 500 750 1000 1500 Feeding quantity kg 800 1200 1800 2400 3600 Mixing power kw 15 18.5 30 37 55 Discharging power kw 2.2 2.2 2.2 3 3 Side Scraper Nr 1 1 1 1 1 Discharge scraper Nr 1 1 1 1 1 Weight (T) kg 1900 2900 4200 5500 6500

Design Feature of Planetary Mixer

Gearing system

Gearing system consists of motor and hardened surface gear,equipped with elastic coupling or hydraulic couple between the motor and reducer. The newly improved gearbox with lower nosie,longer torque and more durable. Even in strict production conditions,the gearbox can distribute power effectively and evenly to each mix and device,ensuring normal operation,high stability and low maintenance of concrete mixer.

Mixing device

Compulsory mixing is realized by composite moves of extruding and overturn driven by rotating planets and blades. Mixing blades are designed in parallelogram structure,which cn be turned 180degree for reuse according to the customer to increase the service life.Specialized discharge scraper has been designed according to discharge speed in order to increase the productivity.

Discharge device

The discharging door can be opened by pneumatic or hydraulic,the number of discharging door max at three,and special sealing device on the discharging door ensure the firm sealing and reliable control.

Hoisting Device

The feeding door of concrete mixer will be opended automaticly when discharging,and closed when the skip hoist hopper is descend.This device effectively prevent the dust flow during the mixing to relaize the environment protection.

Maintenance door and security device

For the sake of safety, high reliable and sensitivity sensor are being installed in the access door,to ensure the safety and convenience during maintenance.

Planetary Concrete Mixer erected up in workshop before shipment to Customer

Container loading of Planetary Mixer to Customers Overseas

Planetary Concrete Mixer application at site

Factory workshop

Our Service

Pre-sale service support

According to every customer's demand and budget, we offer the professional factory set up solution, factory layout design, process flow design. More importantly, we welcome every customer to visit our factory and visit our customer site before placing the order

Send technicians to installation site for the guidance, equipment commissioning and training. Provide high-quality spare parts thoughout the year, and the maintenance technicians are always ready to provide technical help.

Design Feature of Planetary Mixer

Gearing system

Gearing system consists of motor and hardened surface gear,equipped with elastic coupling or hydraulic couple between the motor and reducer. The newly improved gearbox with lower nosie,longer torque and more durable. Even in strict production conditions,the gearbox can distribute power effectively and evenly to each mix and device,ensuring normal operation,high stability and low maintenance of concrete mixer.

Mixing device

Compulsory mixing is realized by composite moves of extruding and overturn driven by rotating planets and blades. Mixing blades are designed in parallelogram structure,which cn be turned 180degree for reuse according to the customer to increase the service life.Specialized discharge scraper has been designed according to discharge speed in order to increase the productivity.

Discharge device

The discharging door can be opened by pneumatic or hydraulic,the number of discharging door max at three,and special sealing device on the discharging door ensure the firm sealing and reliable control.

Hoisting Device

The feeding door of concrete mixer will be opended automaticly when discharging,and closed when the skip hoist hopper is descend.This device effectively prevent the dust flow during the mixing to relaize the environment protection.

Maintenance door and security device

For the sake of safety, high reliable and sensitivity sensor are being installed in the access door,to ensure the safety and convenience during maintenance.

Planetary Concrete Mixer erected up in workshop before shipment to Customer

Container loading of Planetary Mixer to Customers Overseas

Planetary Concrete Mixer application at site

Factory workshop

Our Service

Pre-sale service support

According to every customer's demand and budget, we offer the professional factory set up solution, factory layout design, process flow design. More importantly, we welcome every customer to visit our factory and visit our customer site before placing the order