D8K Dozer Track Single Flange Roller 7s9041

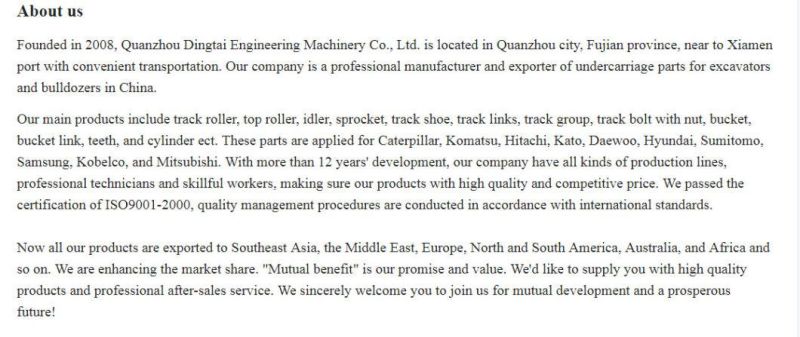

QUANZHOU DINGTAI ENGINEERING MACHINERY CO., LTD.- Type:Bulldozer Spare Parts

- Application:Bulldozer Parts

- Certification:CE, ISO9001: 2000

- Condition:New

- Product Name:Track Roller

- Color:Grey, Yellow, Other

Base Info

- Model NO.:D8K

- Finish:Smooth

- Warranty Time:1 Year

- MOQ:1 Piece

- Time of Delivery:Within 15-25 Days After Contract Established

- Port of Shipment:Xiamen

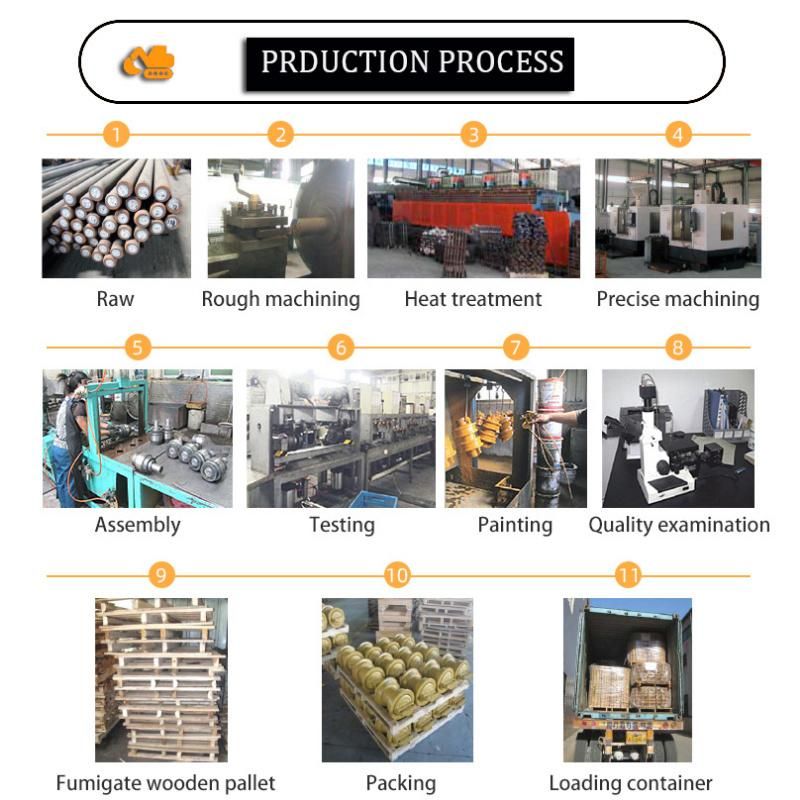

- Technique:Forging & Casting

- Transport Package:as Customer′s Request

- Specification:7S9041

- Trademark:Dingtai

- Origin:Quanzhou, China

- HS Code:84314999

- Production Capacity:50000 Pieces ,Month

Description

Product name

Bulldozer Spare Parts Track Roller/Bottom roller/Support roller

Material

35MnB

Color

Yellow or Black & Customized

Technique

Forging

Finish

Smooth

Surface Hardness

HRC52-58,depth:8mm-12mm

Warranty time

1 Year

Packing

Standard export fumigated wooden pallet

Time of delivery

Within 15 days after contract established

Port of shipment

XIAMEN Port

Payment terms

T/T or L/C or Western Union or Paypal

Our Advantages

1. Products size

Follow OEM strictly

2. One-stop service

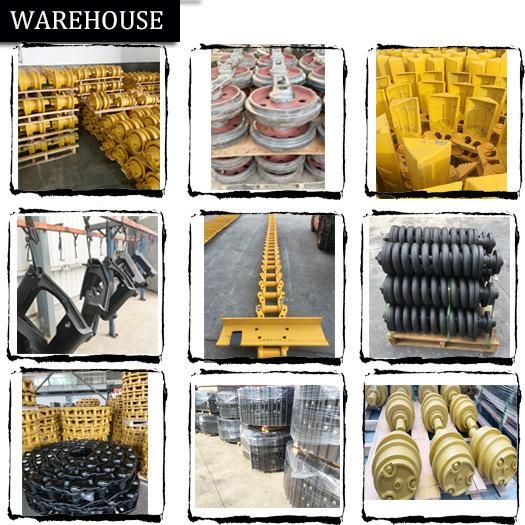

(1)Full undercarriage parts of excavator and bulldozer are available: track roller/bottom roller/lower roller, front idler, sprocket rim/segment group, carrier roller/top roller, track chain with shoes/track group

(2) Excavator spring assembly with OEM size, bucket link/H link, link rod/I link, track guard

(3) Ground Engaging Tools: bucket teeth, excavator buckets, cutting edge, and end bits

(4)Hydraulic cylinder and seal kits:hydraulic cylinders are also available

3. Factory direct price and Strict Quality Control

We have our own factory and foreign trading office, attach much importance to items quality during the production and always check each goods before delivering.

D8K Dozer Track Single Flange Roller 7S9041

3.Feature Of Bottom Roller For Excavator:

1)Our track rollers are adopting through hardening system and spraying quenching system while complying with the stringent ISO System.

2)We are able to assure the part has excellent wear resistance even in the most severe working conditions

3)We are using advance machining centre,horizontal and vertical CNC machining to execute processes such as machining, drilling, threading and milling to ensure the qulity and precision of each component to ensure the accuracy of assembly dimensions. This is to maximize the life span of each component and minimize production cost per hour.

4).Well lubricated oil recycle system

5). High hardness :HRC52-58,deepth:8mm-12mm

D8N Dozer Single Flange Roller 7T9188