Sb81/Sb121 Hydraulic Breaker Steel Pipelines for Excavator

Jinan Changhao Mechanical Equipment Co., Ltd.- Warranty:1 Year

- Type:Hydraulic Breaker Spare Parts

- Application:Excavator

- Certification:CE, ISO9001: 2000

- Condition:New

- Product Name:Hydraulic Breaker Steel Pipelines for Excavator

Base Info

- Model NO.:SB81,Sb121

- Feature:High Efficiency, Long Life

- Color:Customer Required

- Weight:200-1500kg

- OEM:Available

- Delivery:Within 10 Days

- After-Sales Service Provided:Online Support, Free Spare Parts

- Technics:Casting

- Material:Alloy Steel

- Origin Place:Shandong China

- Machinery Test Report:Provided

- Catalog:Hydraulic Hammer Breaker Piping Kits

- Transport Package:Wooden Case, Stretch Film

- Origin:Jinan, China

- HS Code:7304113000

- Production Capacity:10000pieces,Year

Description

Basic Info.

Model NO. SB81/Sb121 Feature High Efficiency, Long Life Color Customer Required Weight 200-1500kg OEM Available Delivery Within 10 Days After-Sales Service Provided Online Support, Free Spare Parts Technics Casting Material Alloy Steel Origin Place Shandong China Machinery Test Report Provided Catalog Hydraulic Hammer Breaker Piping Kits Transport Package Wooden Case, Stretch Film Origin Jinan, China HS Code 7304113000 Production Capacity 10000pieces/YearProduct Description

Product Description

We own advanced production technology and equipment ,which provide reliable guarantee for the quality of our products to meet the demand of the international market. We can also design,develop and manufacture according to the requirements of customers.

Parameter:

| NAME | pipe line |

| Application | Excavator |

| Condition | New |

| MOQ | 1 PCS |

| Catalog | hydraulic hammer breaker piping kits |

| texture | metal |

| Factory Price | Wholesale |

| Feature | High Efficiency, Long Life |

| Transport Package | Carton Packing |

| Origin | China |

| Type | Seal Kits |

| Machinery | Excavator |

| Material | Rubber |

| Delivery | by Air,by Express |

| Pressure | Pressure Type |

| Specification | 0.55kg |

| HS Code | 40169310 |

Main Features

1.Selected raw material - high quality heavy duty wear resistant steel;2. Hydraulic-gas system, increase stability;

3. High-quality and durable wear parts;

4. Advanced manufacturing facilities, introduced from South Korea;

5. High energy and impact frequency (high performance);

6. High-performance optimized hydraulic unit;

7. Low maintenance, less breakdown, long using life;

Company information

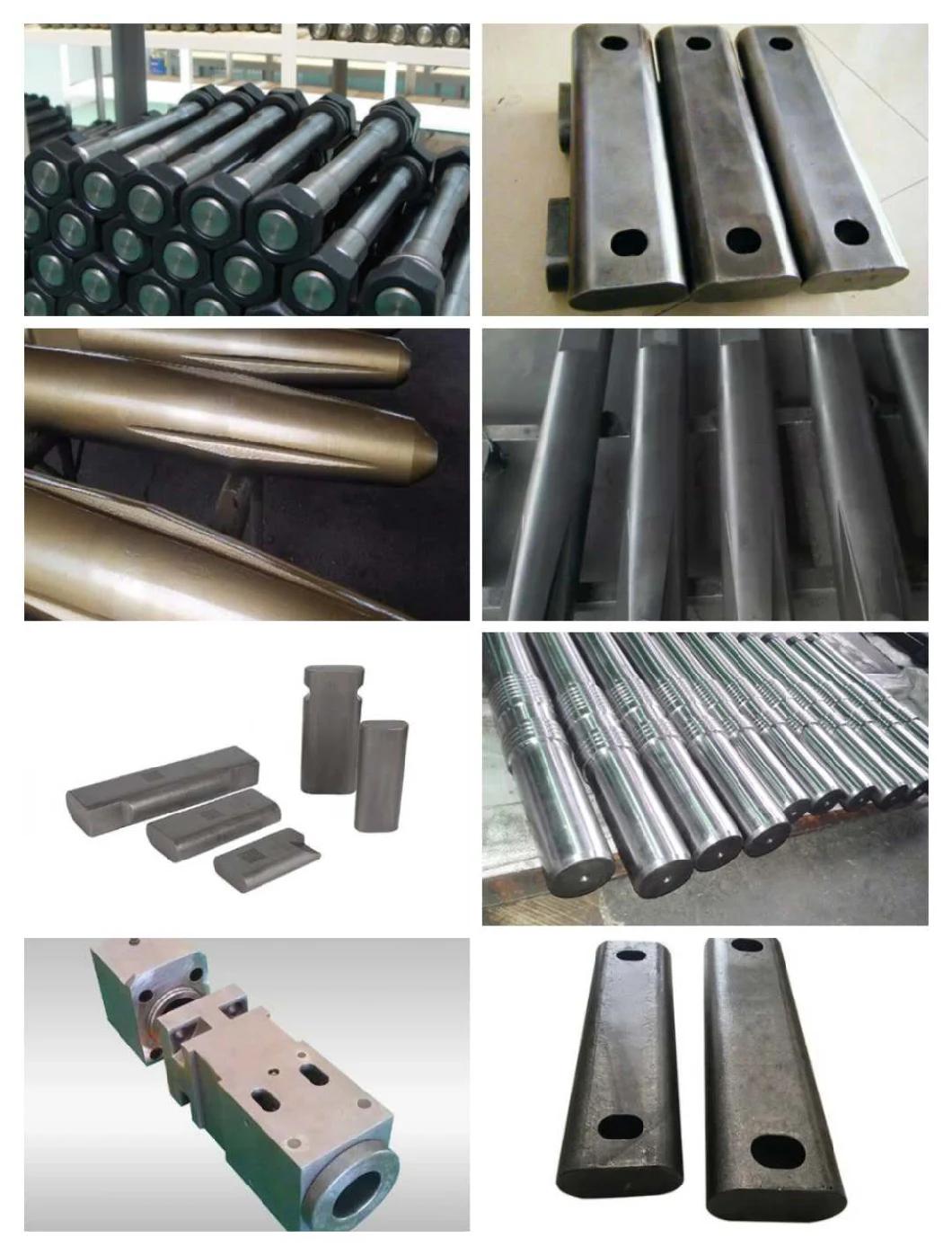

Jinan Changhao Machical Manufacture Co., Ltd professionally engaged in manufacturing various series hydraulic hammers pipeline and its spare parts, such as pipe clamp, ball valve, pipeline tee, pipe to wire,plug, solenoid valve, spare valve, multi-way valve, lock valve, bracket, sensor, hammer tube, arm iron pipe assembly, tee iron pipe, hose, etc. Our company has perfect production equipment and test devices.

Our products have been exporting to many countries in the world with advanced machines and strict quality control management, the advanced production equipment and impeccable QC system help us make sure the highest-quality and cost-effective products.Our products have reached the international advanced level. Cooperating with large number of well-known dealers in the domestic and foreign market.

Product description

All of our pipelines are acid-washed and phosphated to ensure that the inside of the pipeline is clean and dust-free, and the hydraulic system of the excavator is clean and pollution-free.

The outer surface of the pipeline is sprayed with plastic paint, and the colors are various, which are exactly the same as the color of the excavator body. Meet all your requirement for color.

All the accessories of our pipeline, including clamps, ball valves,pipeline tee, pipe to wire,plug, solenoid valve, spare valve, multi-way valve, lock valve, bracket, sensor, hammer tube, arm iron pipe assembly, tee iron pipe, hose etc, are independently developed and manufactured by our factory to ensure product quality, safety and reliability.

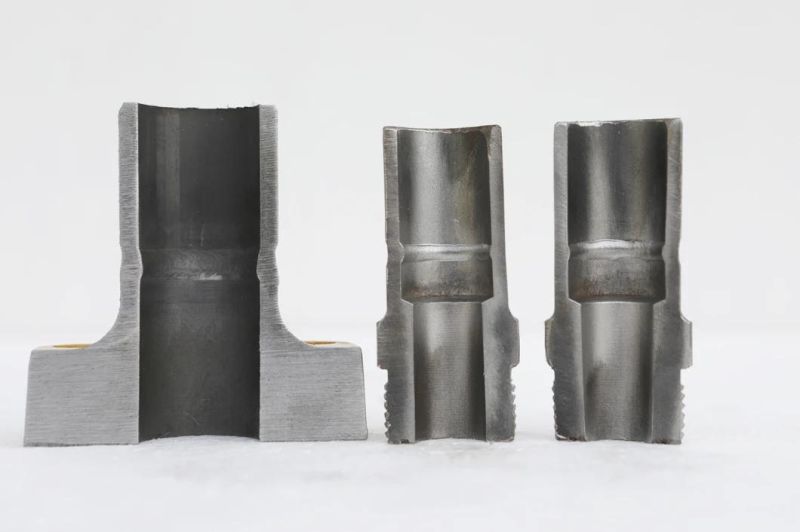

Welding profile

We use the first-class welding machine to weld, after welding, it can achieve the effect of single-sided welding and double-sided forming to ensure that the pipeline will never leak oil.

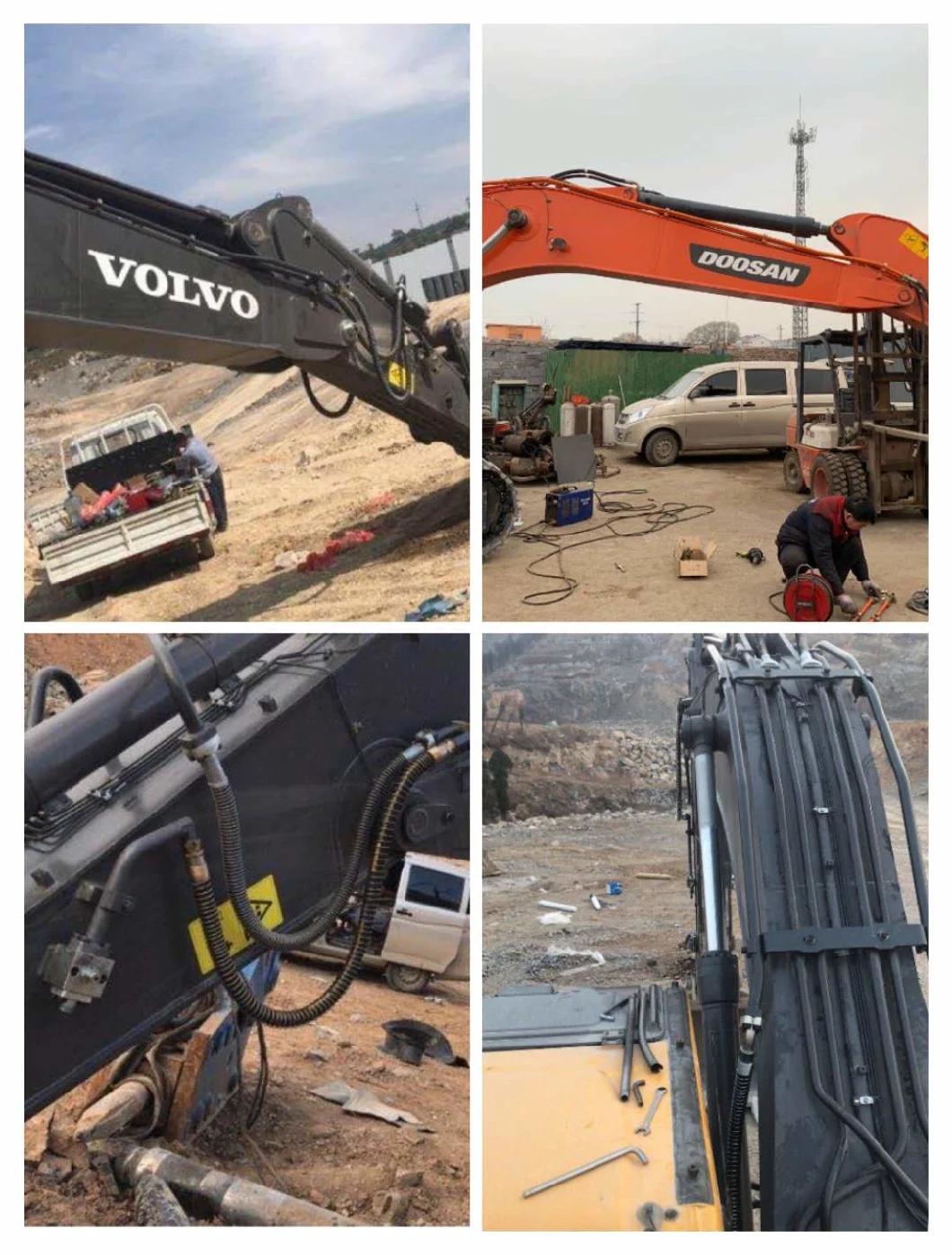

Pipeline installation

Hot Sell Products

Our Certificate

Packing & Shipping