130 Excavator Electromagnet Machine for Sale

Quanzhou Jingli Engineering & Machinery Co., Ltd.- Type:Wheel Excavator

- Usage:GM Excavator

- Bucket:Electro Magnet

- Transmission:Hydraulic Transmission

- Drive Type:Internal Combustion Drive

- Bucket Capacity:0.1~0.5m³

Base Info

- Model NO.:150S

- Size:Medium-Sized

- Certification:ISO9001: 2000

- Condition:New

- Engine Model:Cummins

- Rated Speed:2200r,Min

- Tyre Model:900

- Transport Package:Nude Packing

- Specification:7200*2500*3000mm

- Trademark:JingGong

- Origin:China

- HS Code:8429521100

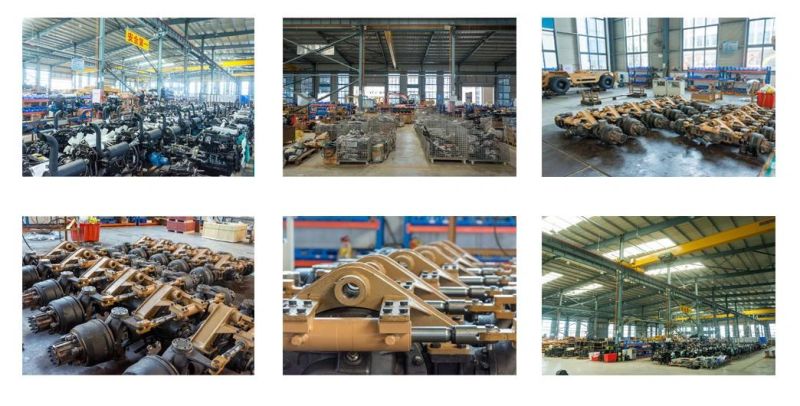

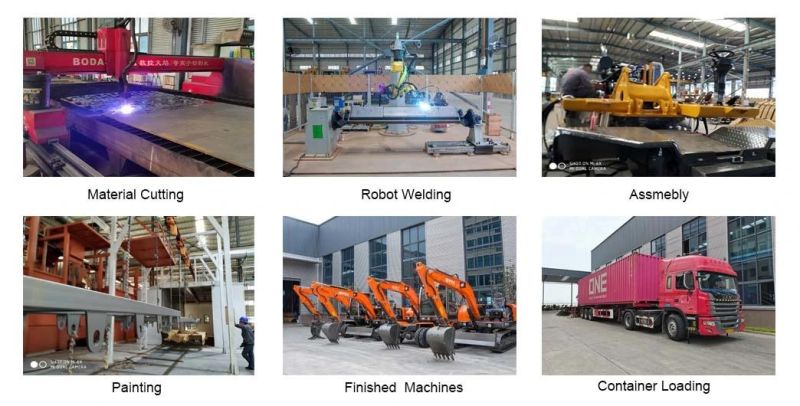

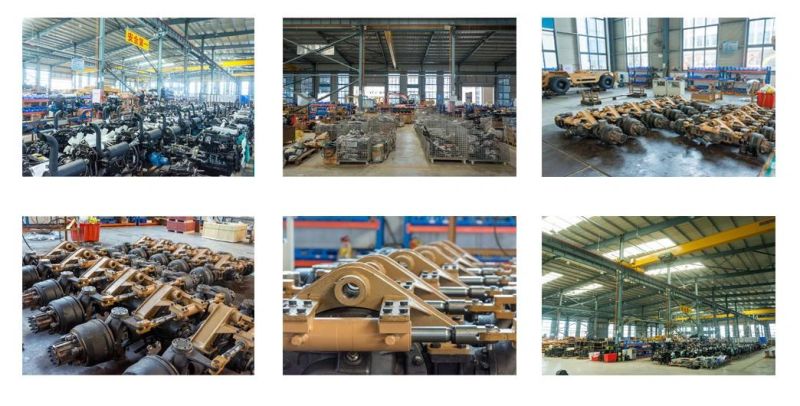

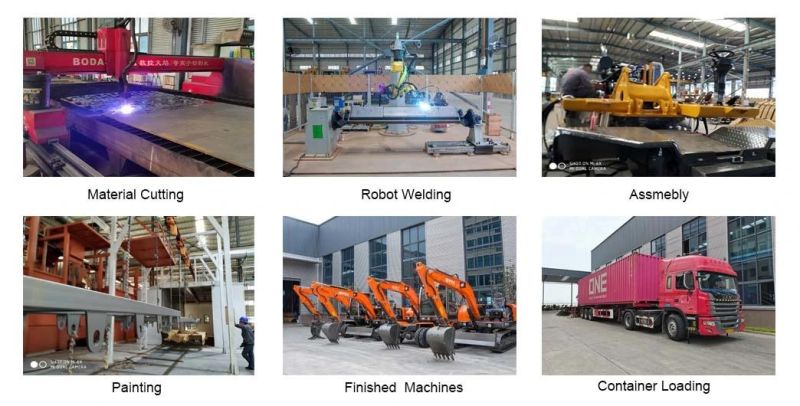

- Production Capacity:3000units, Year

Description

200L

Our company's quality policy: innovative technology, upgrade products, continuous improvement, sincere service;

Quality goal: the pass rate of finished products of conventional products reaches 98% or more in one test. The user satisfaction rate reached over 98%. Every year, we develop 1 ~ 2 new products that meet customer requirements and have development prospects.

We provide more optional parts to complete more kinds of work. We provide a variety of work tools such as grabs, forks, pulverizers, etc. to meet your various application needs. In addition, a variety of fixtures are provided to optimize the performance of the machine. The auxiliary hydraulic lines are arranged on the base of the boom, making the auxiliary hydraulic circuit easier to install, thereby reducing the time, parts and costs required for installing work tools.

Our company's quality policy: innovative technology, upgrade products, continuous improvement, sincere service;

Quality goal: the pass rate of finished products of conventional products reaches 98% or more in one test. The user satisfaction rate reached over 98%. Every year, we develop 1 ~ 2 new products that meet customer requirements and have development prospects.

We provide more optional parts to complete more kinds of work. We provide a variety of work tools such as grabs, forks, pulverizers, etc. to meet your various application needs. In addition, a variety of fixtures are provided to optimize the performance of the machine. The auxiliary hydraulic lines are arranged on the base of the boom, making the auxiliary hydraulic circuit easier to install, thereby reducing the time, parts and costs required for installing work tools.