Hot Sale Metal Square Downpipe Roll Forming Machinery for Rainspout

Hangzhou WILLING INTERNATIONAL CO., LTD.- Material Specification:Aluminum, Coated Aluminum, Galvanized and Painted

- Thickness:0.3 mm to 0.8mm

- Main Motor Power:7.5 Kw

- Hydraulic Station Power:4 Kw

- Feeding Width:398mm

- Cover Width:Model# Wlfm89-118 Is 118mm

Base Info

- Model NO.:as your requests

- Coil Stress:Q235 MPa (33ksi); Maximum Stress Yield Is Q345MPa

- Roll Forming Speed:10~12 M,Min

- Manual Uncoiler:Max. Capacity: 3000kgs

- Type of Cutting:Roll-Formed and Length-Set Cutting

- Transport Package:Wooden Box and Container

- Specification:ISO9001, CE Standard

- Trademark:WILLING INT′L

- Origin:China Pr

- Production Capacity:150 Sets Per Year

Description

Other elements from famous suppliers in China

4. Process Sketch:

Uncoiling → Sheet Guiding → End Cutting → Roll Forming → Measuring Length& Shearin → Sheet to Support Table

5. Standard Equipment of Machine:

Manual Uncoiler 1pc

Guiding Equipment 1set

Roll Forming Equipment 1set

Hydraulic step press equipment 1set

Post Cut Equipment 1set

Hydraulic Station 1pc

PLC Control Penal 1pc

Supporter Table 1set

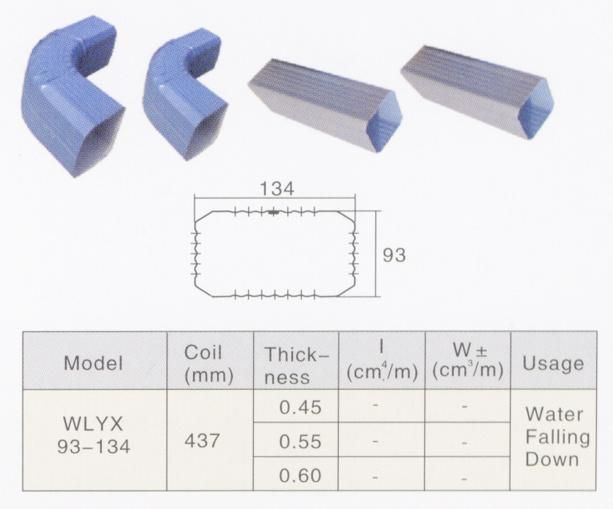

6. Series Design Of Product

Our services:

1. Professional engineers are available to be sent to the customers' factory to install and debug the machines and train the staff how to operate and maintain the machines.

2. We can design different kinds of profiles and fittings for machine, as per customer's requirements. You can send me the profile drawing and we will design the machine for you.

3. Every process will be checked by responsible QC which insures every product's quality.

4. Professional packing teams which keep every packing safely.

(1) Rollers are put on anti-rust oil and packed by bubble wraps; some other electric parts are packed by bubble wraps as well.

(2)The oil hose and electric wires ae marked, and easy to be connected when used;

(3)In container loading, sea-worthy, well fixed by wire rope, wooden block and nails.

5. One-year warranty will be assured for all our machines. Moreover, We promise to provide permanent technical support and after-sales service with our customers.

6. We warmly welcome you to visit our factory for more detailed information, inspecting our machines and we will pick you up at HangZhou Railway station.

FAQ:

1. Q: Are you manufacture or trrading company?

A:We are manufacturer & exporter who signed in 2004, and our boss has many years experiences in machinery.

2. Q: Why should I choose you?

A:We are professional manufacture company that could provide the best products for the best price, high quality of services, and credible quality assurance.

3. Q: How does your factory conduct Quality Control and Inspection?

A: We are quite proud of our quality control procedure. It's comply with ISO quality system to control produce from the raw materials received to finishing warehousing. Any imperfect articles are rejected by our quality control.

4. Q: How many kinds of products do you produce?

A: We have produced different kinds of Steel Roof Tile Roll Forming Machine, Corrugated Steel Sheet Roll Forming Machine, C/Z Purlin Roll Forming Machine, Steel Deck Roll Forming Machine, Slitting Line, Cut to Length Line, Press Brake, Shearing Machine, PPGI ,Gi ,PPGL ,Gl, Aluminum Coil. And we also can provide its finished products.

5. Q: Where is your factory located? How can I visit there?

A: Our factory is located in TongXiang, ZheJiang province. We could pick you up from HangZhou East Railway Station or TongXiang Railway Station when you come.

Please feel free to contact me for more up-date information and any queries you have. Best quality machines and services will be provided for you.